What are jigs and fixtures?

Manufacturing aids are an important part of any manufacturing industry. They ease the entire manufacturing process from start to end be it manually operated or fully automatic. Jigs help holds the position or guide the tool in a specific orientation to execute the manufacturing operation. It is a part specifically made to ensure repeated operations with high accuracy. For example, drill bushings are used to guide the drill tool for drilling, boring, tapping operations etc to ensure precise positioning and drill angle resulting in higher work quality and increased production output.

On the other hand, fixtures are used to firmly hold the part in a specific orientation and location so that manufacturing operations can be performed on the part. Vice used to hold the part for CNC machining is the simplest example of the fixture. Fixtures are important to enable automation and a high rate of production. There’s hardly any manufacturing industry where fixtures are not used. In a mass production set-up like automobile manufacturing, various types of fixtures are used such as manufacturing fixtures, assembly fixtures, paint fixtures, inspection fixtures, transportation fixtures etc. Applying Jigs and fixtures jointly will ensure desired dimensional accuracy and quality of the part to meet the functional requirements.

How are jigs and fixtures made?

Conventionally, Jigs and fixtures are first designed digitally using CAD software according to the part geometry and manufacturing process and then made by CNC or manual process depending according to the level of precision needed. Jigs and fixtures are either single parts or assemblies of multiple components. Choice of material again depends upon the type of manufacturing set up, and precision needed and can be made in metal as well as plastics. Plastics are cheaper and meet most of the performance requirements.

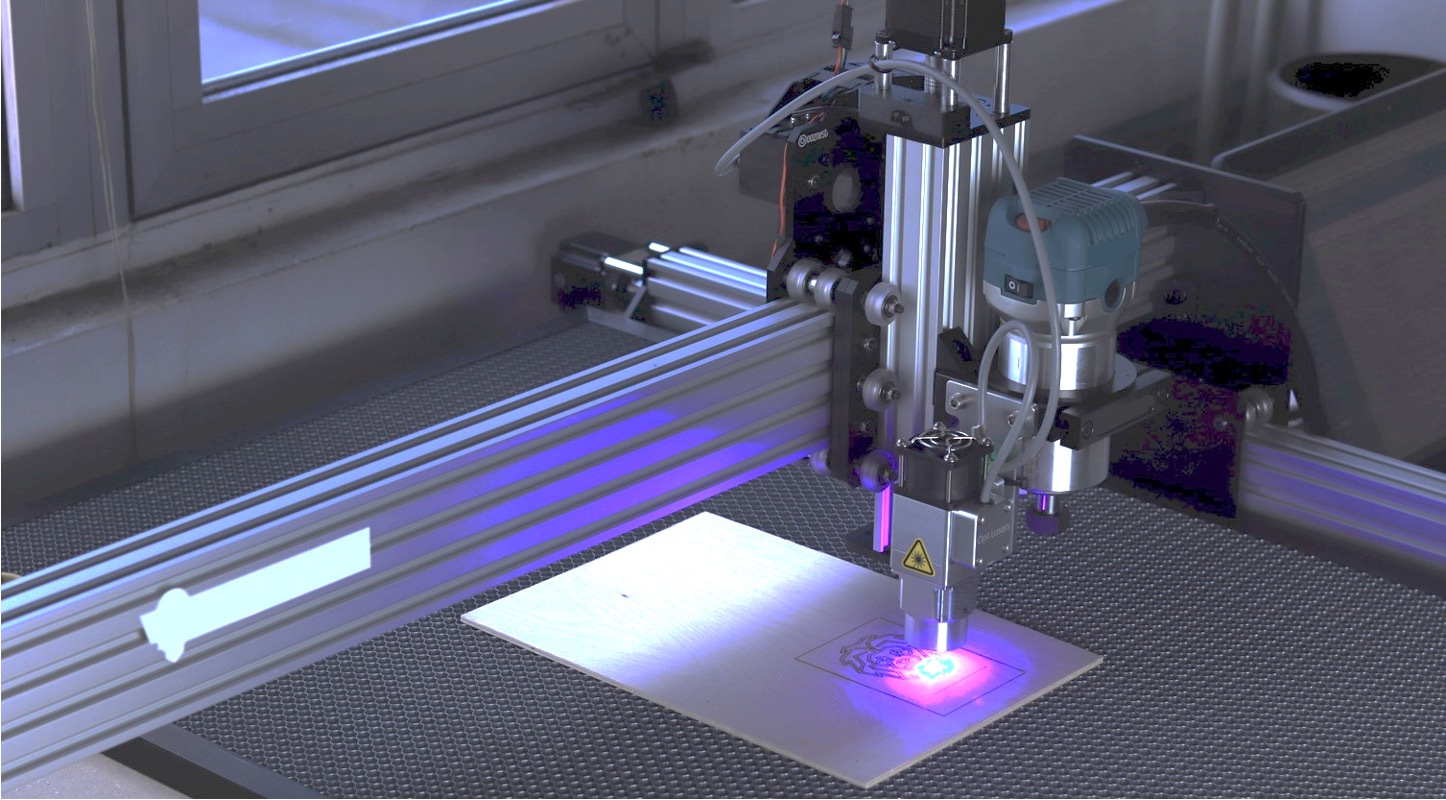

3D printed jigs and fixtures

Jigs and fixtures are designed conventionally but are made by additive manufacturing/3D printing process. 3D printed jigs and fixtures not only saves the manufacturing lead time but can be made at the fraction of the cost of conventional manufacturing. Complex shapes can be made which is not possible by conventional manufacturing setups. Fixtures manufacturing is usually outsourced but in the case of AM, the parts can be received very quickly from a 3D printing service provider. 3DSculpLab can help customers get their 3D printed fixture parts as fast as one day and can 3D print components both in plastics and metals as per customer needs. 3D printing technologies generally used for making are FDM, SLA, SLS, and MJF.

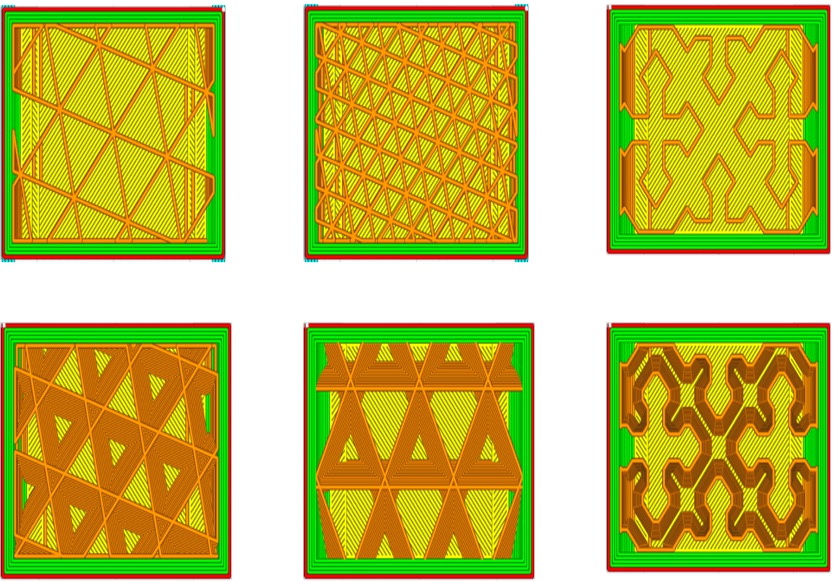

- FDM – FDM (Fused Deposition Modeling) is used for making jigs & fixtures where accuracy and precision are not a major concern. FDM offers low cost and faster turnaround time with minimum post-processing. Parts are ready to use immediately after printing with minimal or no post-processing. Designers should create the design keeping DfAM principles in mind to get the best out of 3D printing.

- SLA – SLA(Stereolithography) is the desired choice for making jigs and fixtures where precision and accuracy are important. However, SLA is suitable for making small size and complex shapes and offers excellent surface quality and dimensional stability with medium functional strength and durability.

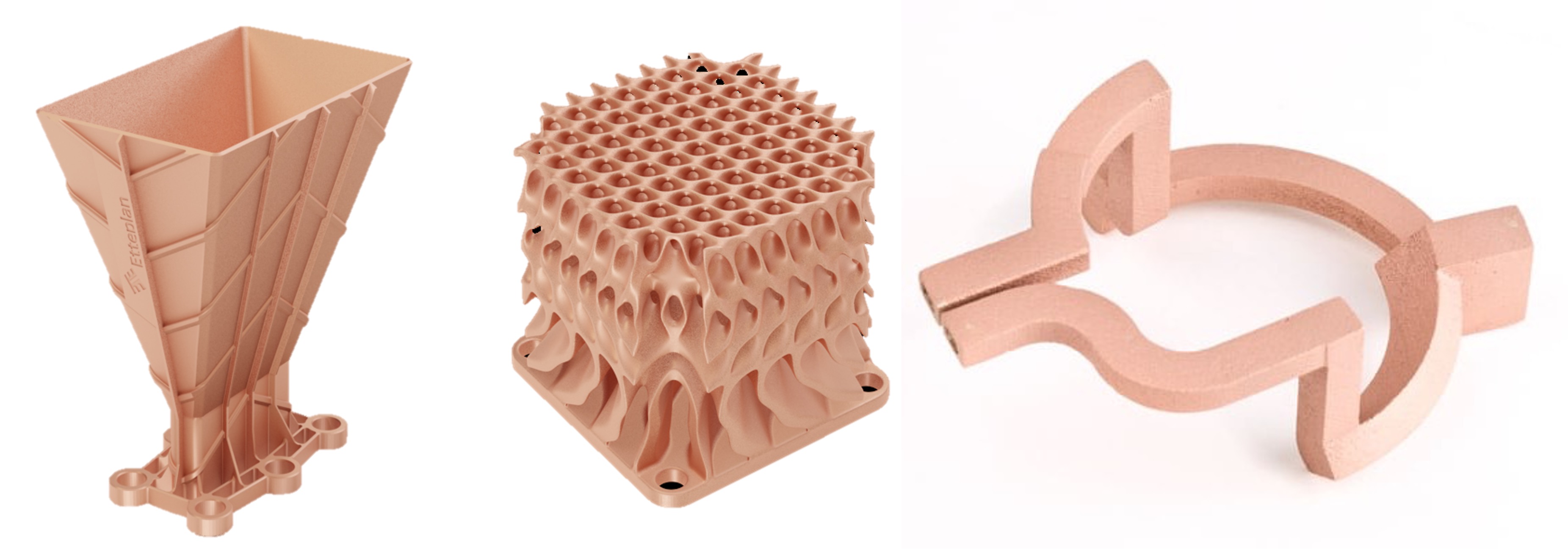

- SLS – SLS 3D printing is another affordable manufacturing solution suitable for large-size jigs and fixtures due to the large build volume of SLS machines. SLS-made jigs and fixtures are more durable than those made by SLA 3D printing but with rough & grainy surface textures lacking smaller features.

- MJF – MJF (Multi Jet Fusion) is another versatile SLS AM process slowly becoming popular for manufacturing jigs and fixtures. MFJ produces functional and direct application parts faster than any other SLS process in nylon material. The printed part reveals smaller details, better surface finish and mechanical characteristics compared with other SLS processes. Near constant wall thickness and corner, radiuses are key to avoiding part defects and keeping dimensions within tolerance.

- SLM – SLM(Selective Layer Melting) or metal 3D printing makes jigs and fixtures which are exceedingly stronger than any other 3D printing technology. Delivery time is slightly longer due to multi-step post-processing steps involved like heat treatment and machining to meet dimensional accuracy.

Advantages of 3D printed jigs and fixtures

- Fast turnaround – Shorter lead time is the greatest advantage of 3D printing. Parts are delivered within a day or even in a few hours depending upon the size and complexity of the design resulting is enhanced productivity and shorter downtime.

- Cost-effective – In some cases, 3D printing is the most cost-effective solution for customized products where multiple jigs and fixtures are required with minor changes.

- Complex shapes – 3D printing has the capability to produce highly complex geometries which are not possible thru conventional manufacturing like CNC, and injection molding. Topology optimization can further make the design leaner and less weight by using its AI-based algorithm to create shapes which are almost impossible to imagine.

Applications

- Custom Vice jaws

- Drill bushings

- Inspection gauges

- Assembly fixtures

- Dismantling fixtures

- Joining fixtures

- Fixtures for signs & labels

- Part substitution

Custom vice jaws

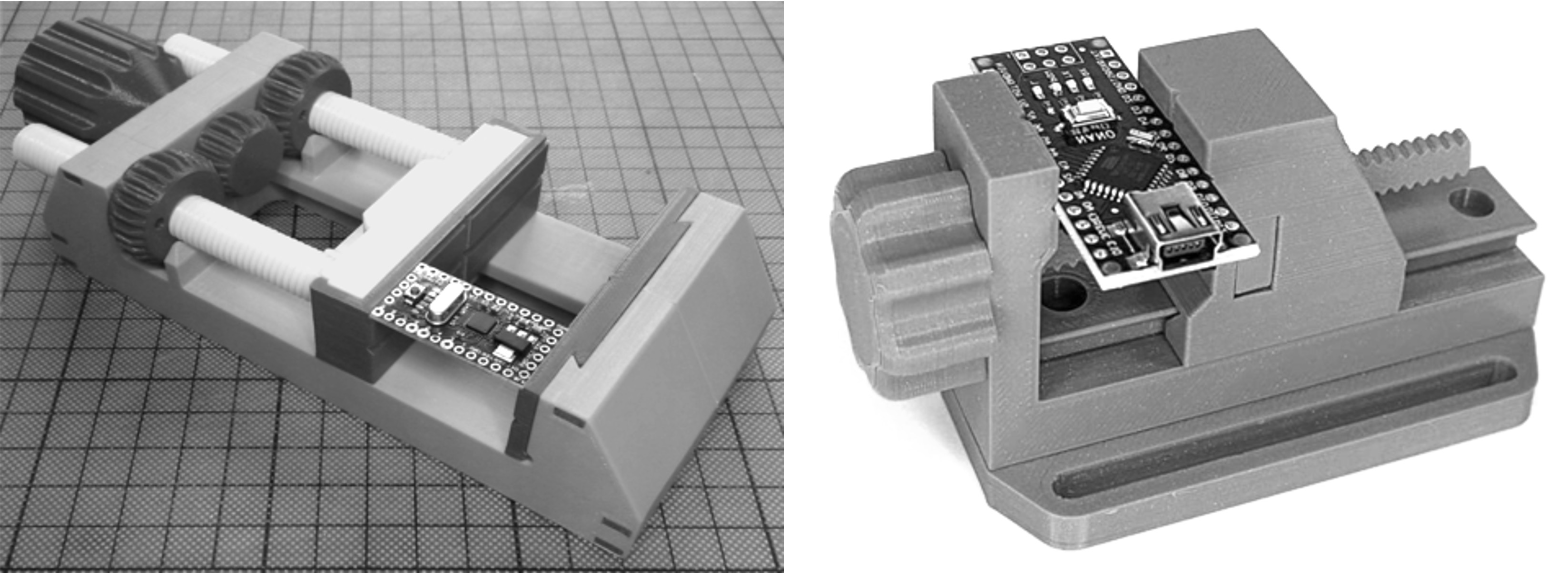

Vice jaws are custom-made part holding inserts matching the shape of the part. This helps in avoiding surface damage, deformation and scratch during handling or when the manufacturing process is underway. Soft jaws made in plastic are useful for holding critical and delicate parts like watchmaking, electronic parts etc.

3D printed custom vice jaws for assembly. Photo credit: Thingiverse

Drill bushings

Drill bushings or guides are useful in holding the drill to ensure positional accuracy of the hole by firmly aligning the bit axially.

3D printed custom drill jig. Photo credit: Thingiverse

Inspection gauges

Inspection gauges are the fastest way to ensure the product meets the desired quality be it dimensions, size or shape. Inspection gauges are important because they quickly identify errors in physical parts which are critical to the application. 3D printed gauges are useful and cost-effective where customizations are introduced into the product as per customer needs. Manufacturing the gauges by conventional methods is not only time-consuming but cost prohibitive as well in some cases.

3D printed profile inspection gauge. Photo credit: Thingiverse

Assembly fixtures

Many products are assemblies of many individual components. Sometimes fixtures are required to ensure the correct assembly procedure. The Assembly fixture will hold the part in a specific orientation so that the union happens correctly as desired. 3D printed assembly fixtures are most suitable for delicate assemblies like watches, medical equipment, and electronic parts as they can be made in any shape. Assembly fixture will ensure error-free operation with a high degree of repeatability.

3D printed PCB assembly test fixture. Photo credit: PCBWay

Dismantling fixtures

Just like assembly fixtures, there are dismantling or disassembly fixtures. Dismantling fixtures are used to disassemble the multi-part product without damaging the internal and external components for repairs, re-work, realignment etc. For a snap-fit-like design, the fixture will ensure all snaps are unlocked at the same time avoiding the risk of any damage during handling.

3D printed disassembly fixture. Photo credit: Formlabs

Joining fixtures

Joining or adhesive bonding fixtures are used to create a bond between one or multiple parts in an assembly by aligning them correctly. 3D printed plastic joining fixtures are a more cost-effective option than machined plastics or metal parts for delicate parts like electronic enclosures, safety-critical items etc. it is very useful in ensuring error-free bonding.

3D printed car wheel bolt assembly fixture. Photo credit: Ultimaker

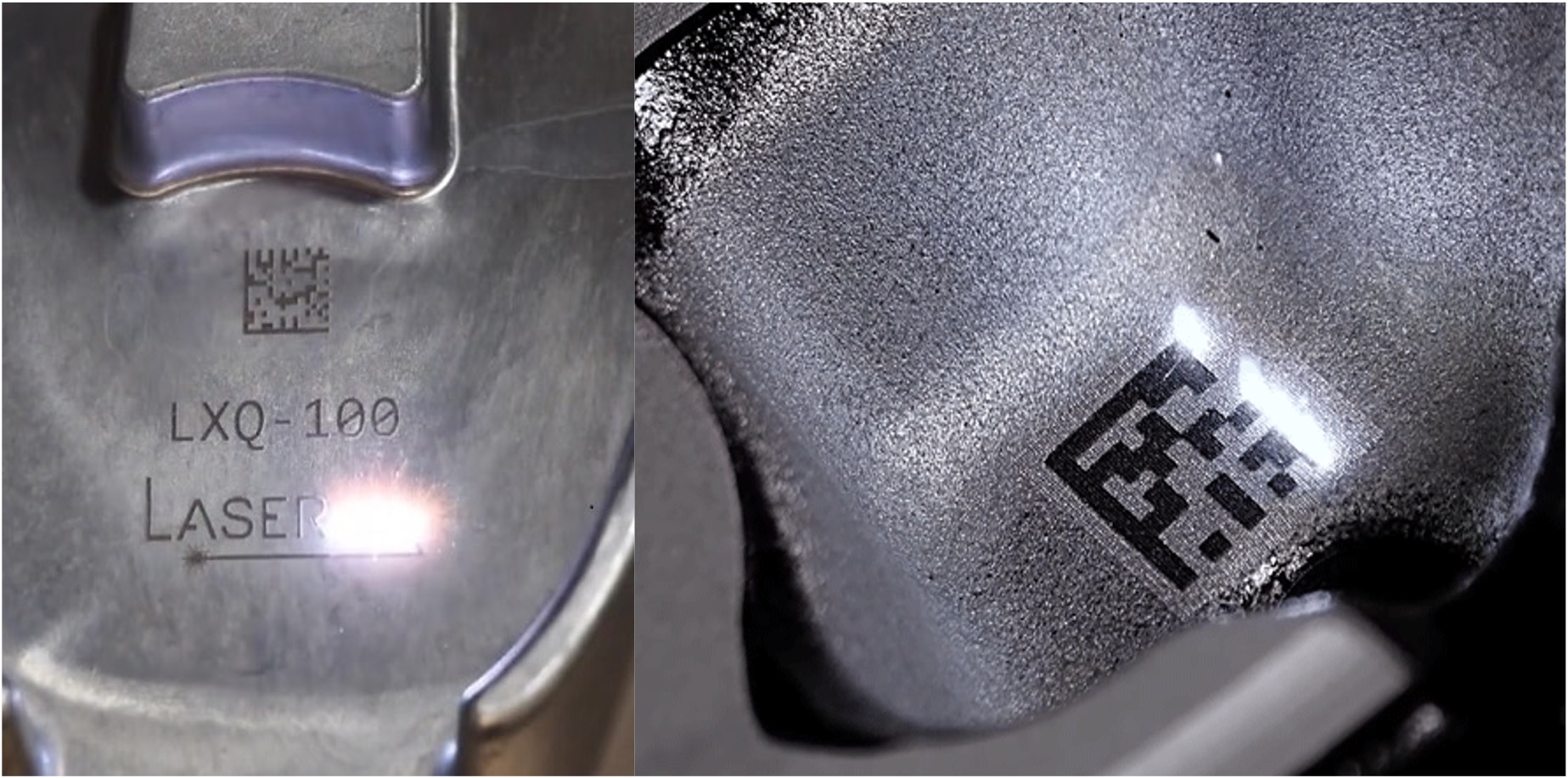

Fixtures for signs & labels

3D printed fixtures are immensely useful and low-cost options for fixing the labels or signs at the correct location and orientation be it automobiles, consumer goods etc. It’s a great option for custom label fitment when only a few labels are required to be fixed for a specific requirement.

3D printed car logo assembly fixture. Photo credit: Ultimaker

Part substitution

For example, you want to test the fixture performance under circumstances critical to product handling or the manufacturing process. Trials done on the 3D printed jigs and fixtures can help designers weed out any deficiency in the performance before committing it for final production thru conventional manufacturing. Also, save on fixture development costs and lead time.

Conclusion

3D printing has the potential to unlock the creativity limited by the designer's imagination be it jigs and fixtures or any other product. A designer can also leverage advanced AI-based design optimization software available in the market to create complex fixtures designs suitable for a complex geometry product. For large-scale customizations, 3D printing is the best and most cost-effective option to develop the custom equipment required for its manufacturing.

Blog created by - The 3D SculpLab Team

3D SculpLab

3D SculpLab