- 34 materials

- Lead time from 2-3 weeks

Prototype And Low Volume Production

See more

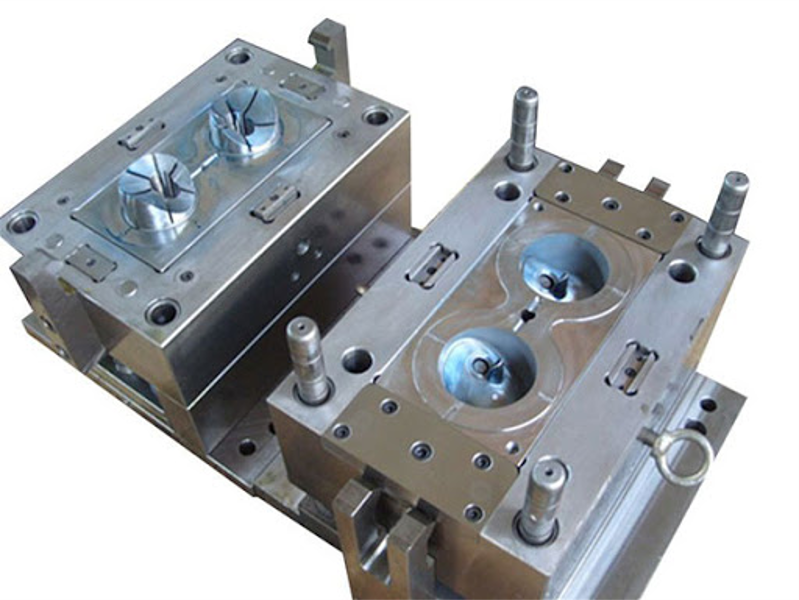

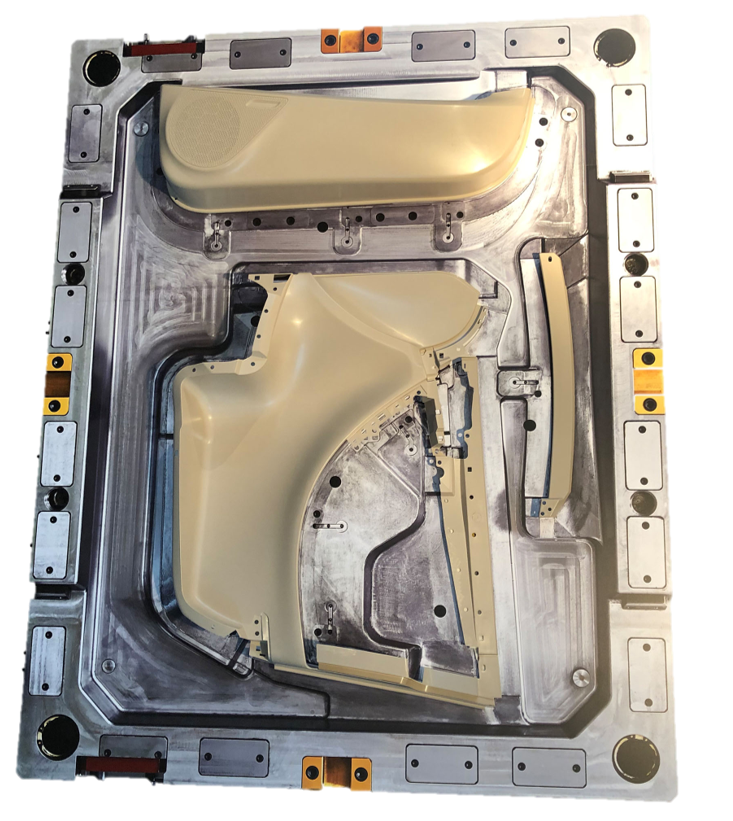

Proto Tool | Production Tool

Get a quick quote

Materials

Get off tool parts in 2~3 weeks

Upload Cad

Select Material

Select Finish

We Make it

Get your parts

| Polish Std. | Surface Finish | Polish Method | Roughness Value Ra (μm) |

Remarks |

|---|---|---|---|---|

| As machined | Default machine finish | 3.2μm | ||

| A-1 | High Shiny finish | Grade #3, Diamond Buff | 0.012 to 0.025 |

High polish finish For mirror & optical finishes |

| A-2 | Medium Shiny finish | Grade #6, Diamond Buff | 0.025 to 0.05 | |

| A-3 | Normal Shiny finish | Grade #15, Diamond Buff | 0.05 to 0.10 | |

| B-1 | High Semi-glossy finish | 600 Grit Paper | 0.05 to 0.10 |

Paper type finish. Removes all tool and machining marks. Light reflecting finish on molded part with some sheen. |

| B-2 | Medium Semi-glossy finish | 400 Grit Paper | 0.10 to 0.15 | |

| B-3 | Normal Semi-glossy finish | 320 Grit Paper | 0.28 to 0.32 | |

| C-1 | High Matte finish | 600 Grit Stone | 0.35 to 0.40 |

Stone finish. Removes all tool and machining marks. Mute finish on molded part. No sheen. |

| C-2 | Medium Matte finish | 400 Grit Stone | 0.45 to 0.55 | |

| C-3 | Normal Matte finish | 320 Grit Stone | 0.63 to 0.70 | |

| D-1 | Satin Textured finish | Dry Blast Glass Bead #11 | 0.80 to 1.00 |

Dry blasted finish. For decorative finishes. Helps hide shrink marks and other imperfections. Dull, non reflecting finish on molded part. |

| D-2 | Dull Textured finish | Dry Blast #240 Oxide | 1.00 to 2.80 | |

| D-3 | Rough Textured finish | Dry Blast #24 Oxide | 3.20 to 18.0 |

If the services you're looking for are not available, please do let us know, we'll get for you.

Get Quote