- 34 materials

- Lead time from 2-3 weeks

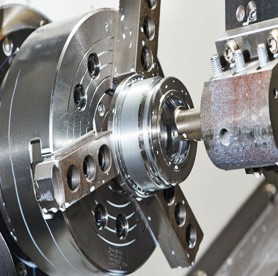

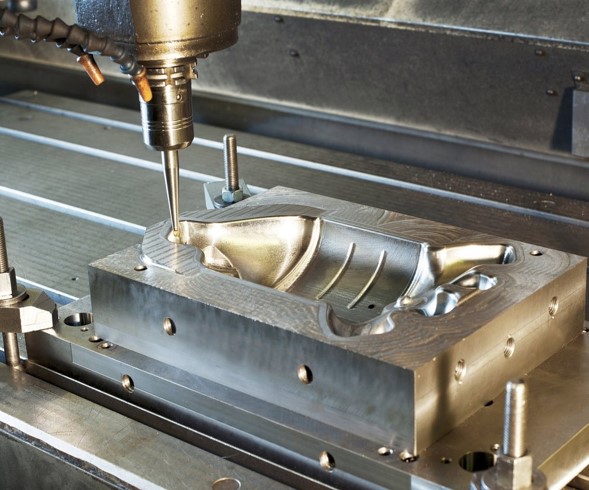

Prototype And Low Volume Production

See more

Upload Cad

Select Material

Select Finish

We Make it

Get your parts

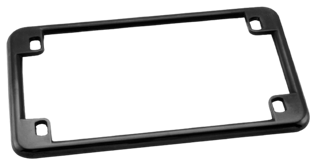

| Surface Finish | Image | Remark |

|---|---|---|

| As machined (Ra 3.2 µm) |  |

|

| Smooth Finish (Ra1.6µm) |  |

|

| Brushed (Ra1.2µm) |  |

|

| Polished (Ra0.8µm) |  |

|

| Powder coated |  |

|

| Satin finish (Beed blast) |  |

|

| Matte Finish (Beed blast + Anodized typ2) |

|

|

| Glossy finish (Brushed + Anodized typ2) |

||

| Hardcoated (Anodized typ3) |

||

| Black Oxide |  |

|

Get a CNC Quote