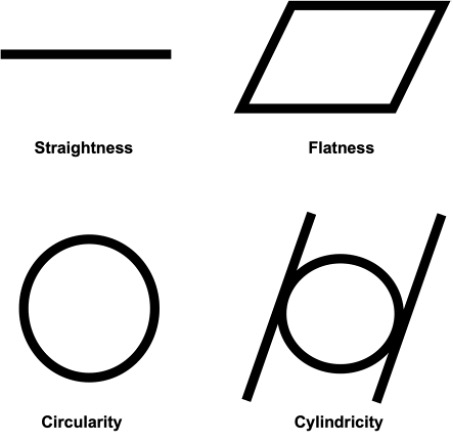

Straightness (Flat Surfaces) —

1. (ASME Y14.5M-1994, 6.4.1)

Straightness is the condition where an element of a surface or an axis is a straight line.

2. (ASME Y14.5M-1994, 6.4.2)

In this example, each line element of the surface must lie within a tolerance zone defined by two parallel lines separated by the specified tolerance value applied to each view. All points on the surface must lie within the limits of size and the applicable straightness limit.

The straightness tolerance is applied in the view where the elements to be controlled are represented by a straight line.

Straightness (Surfaces Elements) —

In this example, each longitudinal element of the surface must lie within a tolerance zone defined by two parallel lines separated by the specified tolerance value. The feature must be within the limits of size and the boundary of perfect form at MMC. Any barreling or waisting of the feature must not exceed the size limits of the feature.

Straightness (RFS) —

Outer Boundary = Actual Feature Size + Straightness Tolerance

In this example, the derived median line of the feature’s actual local size must lie within a tolerance zone defined by a cylinder whose diameter is equal to the specified tolerance value regardless of the feature size. Each circular element of the feature must be within the specified limits of size. However, the boundary of perfect form at MMC can be violated up to the maximum outer boundary or virtual condition diameter.

Straightness (MMC) —

Virtual Condition = MMC Feature Size + Straightness Tolerance

In this example, the derived median line of the feature’s actual local size must lie within a tolerance zone defined by a cylinder whose diameter is equal to the specified tolerance value at MMC. As each circular element of the feature departs from MMC, the diameter of the tolerance cylinder is allowed to increase by an amount equal to the departure from the local MMC size. Each circular element of the feature must be within the specified limits of size. However, the boundary of perfect form at MMC can be violated up to the virtual condition diameter.

Flatness

In this example, the entire surface must lie within a tolerance zone defined by two parallel planes separated by the specified tolerance value. All points on the surface must lie within the limits of size and the flatness limit.

Flatness is the condition of a surface having all elements in one plane. Flatness must fall within the limits of size. The flatness tolerance must be less than the size tolerance.

Circularity (Roundness)

In this example, each circular element of the surface must lie within a tolerance zone defined by two concentric circles separated by the specified tolerance value. All points on the surface must lie within the limits of size and the circularity limit.

Circularity is the condition of a surface where all points of the surface intersected by any plane perpendicular to a common axis are equidistant from that axis. The circularity tolerance must be less than the size tolerance

Cylindricity (Roundness)

In this example, the entire surface must lie within a tolerance zone defined by two concentric cylinders separated by the specified tolerance value. All points on the surface must lie within the limits of size and the cylindricity limit.

Cylindricity is the condition of a surface of revolution in which all points are equidistant from a common axis. Cylindricity is a composite control of form which includes circularity (roundness), straightness, and taper of a cylindrical feature.

Blog created by - 3D SculpLab Team

3D SculpLab

3D SculpLab