Flexibles or rubber-like materials are essential parts of our daily life right from consumer goods to industrial applications. Without flexible materials, certain application and functional requirements cannot be realized like shock absorption, insulations, dampers, seals etc. There is a wide range of flexible materials available for every requirement across a diverse industrial spectrum like Thermoplastic polyurethane (TPU), EPDM, Elastomeric polyurethane (EPU), Flexible Polyurethane(FPU), plastic (PA12) etc. Flexible parts can be produced by various manufacturing technologies such as 3D printing, injection molding, compression molding, vacuum casting etc. Selection of the manufacturing technology depends upon the application requirements such as 3D printing is suitable for fast development of a prototype, proof of concept and short-run production. Whereas injection molding and compression molding is suitable for large-scale mass production. On the other hand, vacuum casting produces parts matching injection molding quality but at a smaller scale. Very few materials options are available to choose from for vacuum casting. In this article, we’re going to talk about various manufacturing technologies for making flexible items and key material properties.

Flexible in 3D printing

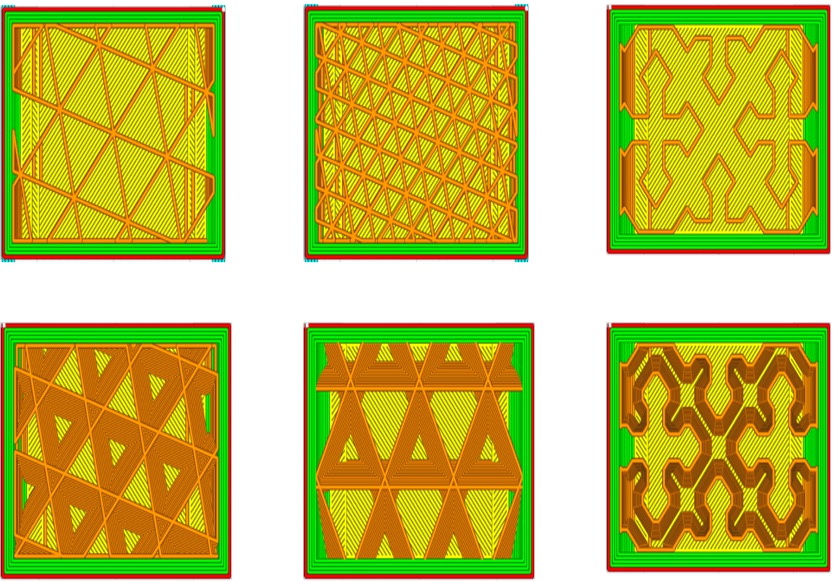

3D printing provides many options when it comes to producing parts in flexible materials. The key advantage is that complex shapes can be created with more ease than other conventional manufacturing technologies. FDM TPU, SLA/DLP Rubber resin, and SLS/MJF Nylon(PA12) are a few of the key materials available for 3D printing.

Thermoplastic polyurethane (TPU)

FDM TPU is an elastomer commonly available in shore A hardness. It is generally used in engineering applications and consumer goods where flexibility along with high tear strength is required along with fine feature details. The unique capabilities offered by the TPU cannot be achieved by other materials like ABS, PLA, PET etc. Merging properties of rubber and plastic, TPU can make designs high on durability and elasticity that can be easily twisted, compressed and bent. TPU’s firm rubber-like properties make it ideal for a wide array of end-use products from industrial grade to consumer grade.

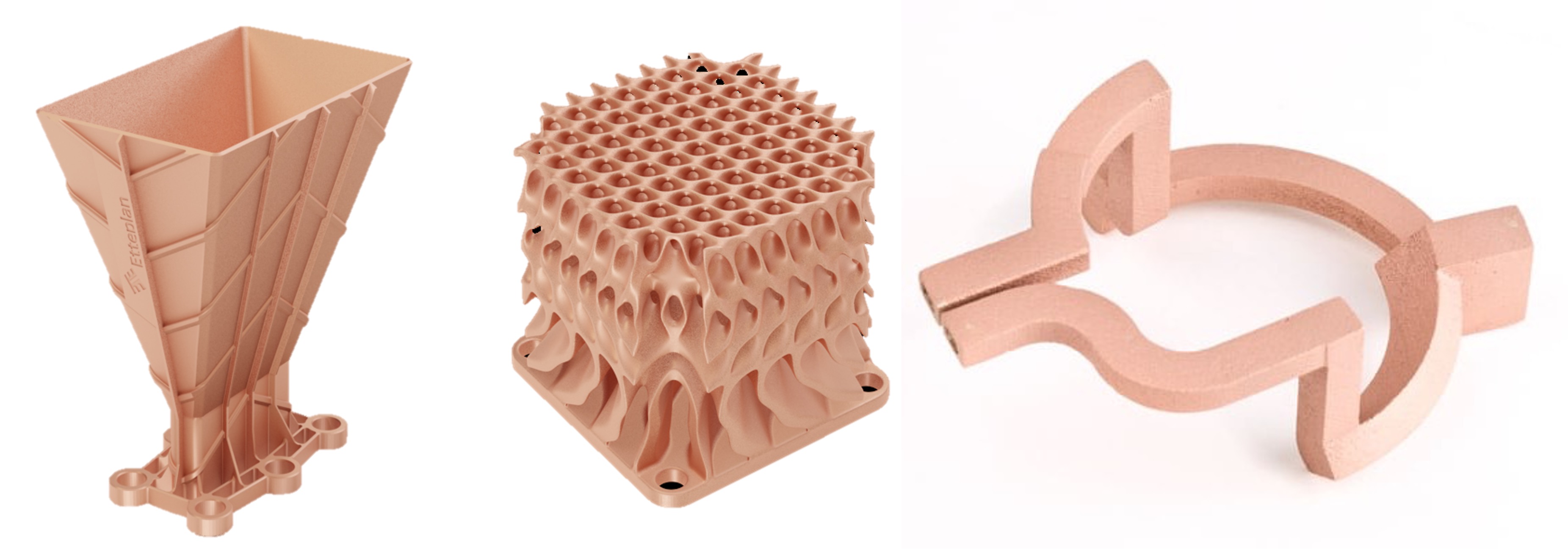

3D printed TPU parts

SLA/DLP Rubber resin

SLA/DLP rubber resins are used in the stereolithography type 3D printing process. 3D Systems Figure 4® RUBBER-65A BLK is created to address the needs for rubber parts featuring production-level performance and mechanical properties tested according to industry standards. Figure 4 RUBBER-65A BLK is a mid-tear strength, high elongation at break, and Shore 65A material to produce medium-hard rubber parts with a slow rebound. Common applications are grips, handles, gaskets, bump stoppers, seals, vibration dampers etc.

Figure 4 Rubber-65A BLK. Photo credits: 3D Systems

SLS/MJF Nylon(PA12)

MJF Nylon(PA12) is a non-abrasive material that is good for ergonomic shapes and holding fixtures for parts that are easily scratched. It can be painted or dyed. Nylon printed parts exhibit some flexibility which is ideal from a fitment and functionality point of view. PA12 is ideal for complex assemblies, housings, enclosures, and watertight applications.

3D printed PA12(Nylon) part

VisiJet® SL Flex

VisiJet® SL Flex or Accura 25 provides a polypropylene-like look and feel and white opaque colour with high flexibility. The part retains its shape and is generally suitable for snap-fit assemblies. Common applications are snap-fit assemblies, general prototyping, and functional parts.

3D printed Accura 25 part. Photo credits: 3D Systems

Flexibles in Injection molding

Injection molding is the process of producing high-quality parts at a mass-production scale. Various flexible materials such as TPU, EPDM, NBR, PVC nitrile are available for the rubber molding process.

Thermoplastic polyurethane (TPU)

TPU parts can also be produced at a large scale by the injection molding process. The physical properties and performance remain the same as highlighted above in the flexible 3D printing paragraph.

Injection molded TPU part

EPDM (Ethylene Propylene Diene Monomer)

EPDM rubber is a low-cost option for parts having outdoor applications, exposure to moisture and electrical insulations, and, has good tear resistance. EPDM exhibits good resistance when exposed to ozone, UV rays, ageing and steam environments. However, EPDM is unsuitable for food applications and vulnerable to hydrocarbon oils, solvents, and some lubricating oils. Also, EPDM is not flame resistant. Common applications are seals, grommets, gaskets, industrial insulations, tubing, and hoses.

EPDM part

NBR (nitrile-butadiene rubber)

NBR is tough and resistant to varying temperatures. The percentage of acrylonitrile decides its oil resistance property. More acrylonitrile means more resistance to oil swelling and gases and makes it stronger. Less acrylonitrile means more flexibility at lower temperatures. NBR is not suitable for some chemicals, outdoor applications, and sunlight and has lower flame resistance. Common applications are oil seals, gaskets, hoses, laboratory equipment etc.

NBR + PVC part

PVC nitrile

It is closed-cell flexible foam created to provide flexible & soft insulation material. It has an excellent performance in hot and cold temperature environments. It has excellent moisture resistance capability saving the enclosed metal parts from corrosion and has some flame-retardant characteristics. Common applications are acoustics, ducting's, HVAC applications etc.

PVC parts

Flexible in vacuum casting

Vacuum casting is another rapid prototyping technology to create high-quality parts but at a smaller scale. In the vacuum casting process, liquid chemicals are mixed and poured into a silicon mold which takes the shape of the mold. Parts are removed once the liquid mixture becomes solid. This sequence is repeated 15~20 times before the silicon mold wears out. As of today, EPDM is the only commonly available material for flexible parts. In future, we may have more flexible materials options available.

Key advantages

- 3D Printing – Key advantage of 3D printing is the cost-effectiveness and quick availability of physical parts for evaluation than parts made by conventional manufacturing. Multiple iterations can be done in a short span of time for initial product validation. A wide range of flexibles is available for almost every requirement.

- injection molding – Injection molding is ideal for mass market production and can produce parts from a few thousand to a million per month. IM per piece costs much lower than any other mass manufacturing technology. Materials like EPDM, NBR, and PVC nitrile are mass produced thru the compression molding process. In compression molding, a rubber piece is kept inside the pre-heated mold which takes the shape of the mold.

- Vacuum casting – Advantages of vacuum casting can produce matching injection molding quality but in small numbers per mold. VC helps designers to visualize parts which are close to the final design or mass market intent. VC part can be painted/ polished as per final product requirements.

Applications of rubber parts

- Automobile – Grips, Handles, Gaskets, Bump stoppers, Seals, Vibration dampers

- Consumer goods – Toys, electronic items, white goods

- Industrial application – O-rings, hoses, gaskets, electrical insulation, Laboratory safety equipment, Acoustics

- HVAC - Tubing, hoses, seals, gaskets, insulations, Chiller & deep freezer applications

Conclusion

Without flexible’s, it's nearly impossible to imagine or create any product. TPU material is most suitable for mass market production depending upon the requirements. Go with EPDM if the application demands outdoor performance. More flexible material options are available on the 3D SculpLab materials page. Just upload the CAD to get an online quote.

Blog created by - 3D SculpLab Team

3D SculpLab

3D SculpLab