Overview

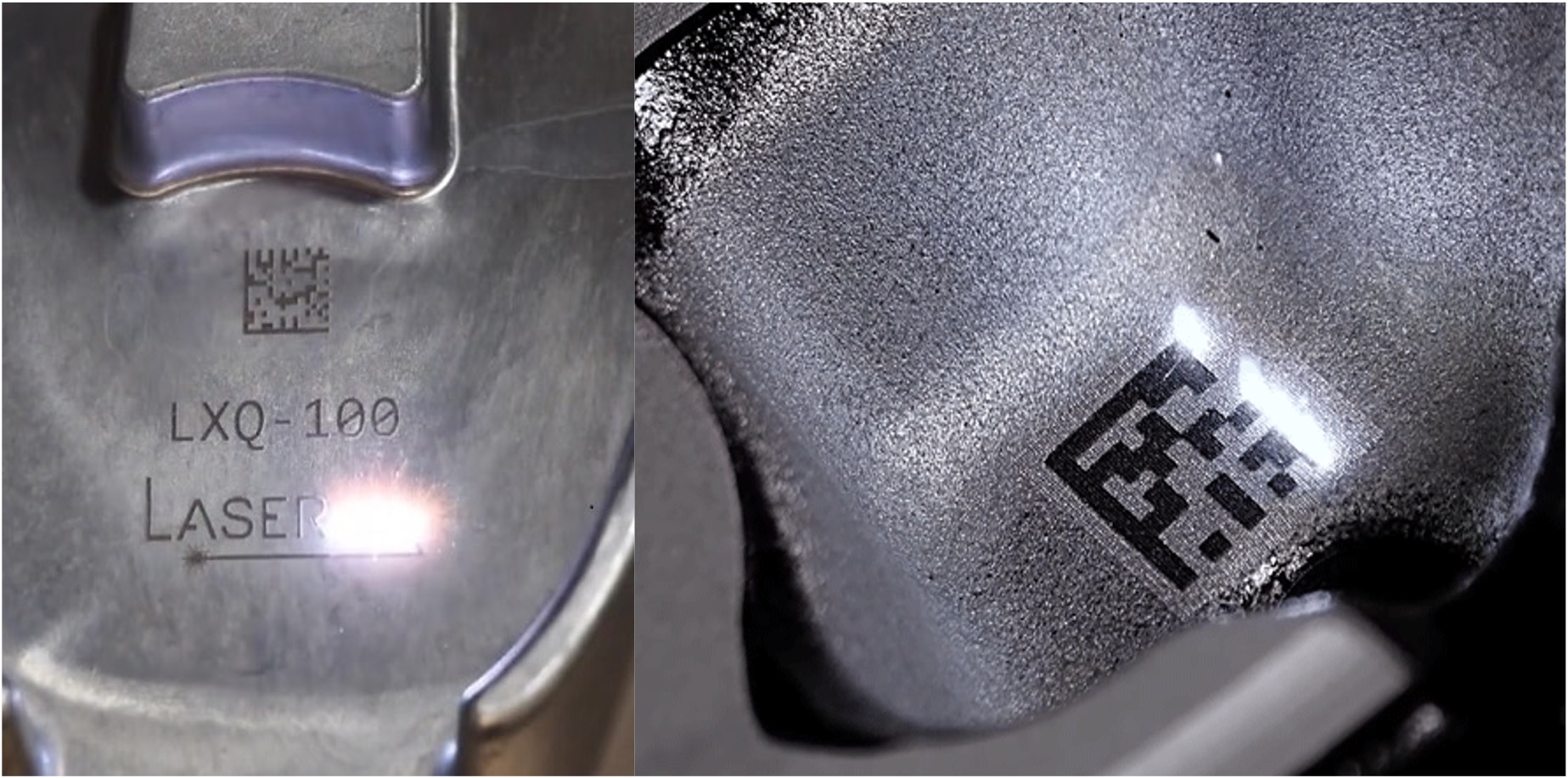

CNC machining is one of the most common types of conventional manufacturing technology generally associated with the machining of metals. CNC produces parts with high precision with applications across the industrial spectrum. Plastic materials are also CNC machined to produce high-quality parts. We all know CNC machining is a subtractive manufacturing process where the material is removed from the stock to gain the desired shape. Depending upon the design complexity, the operator would select if 3axis, 5axis or 6axis machine is suitable for the job. Added complexity also increased the need for high precision, complex set-up preparation and programming etc.

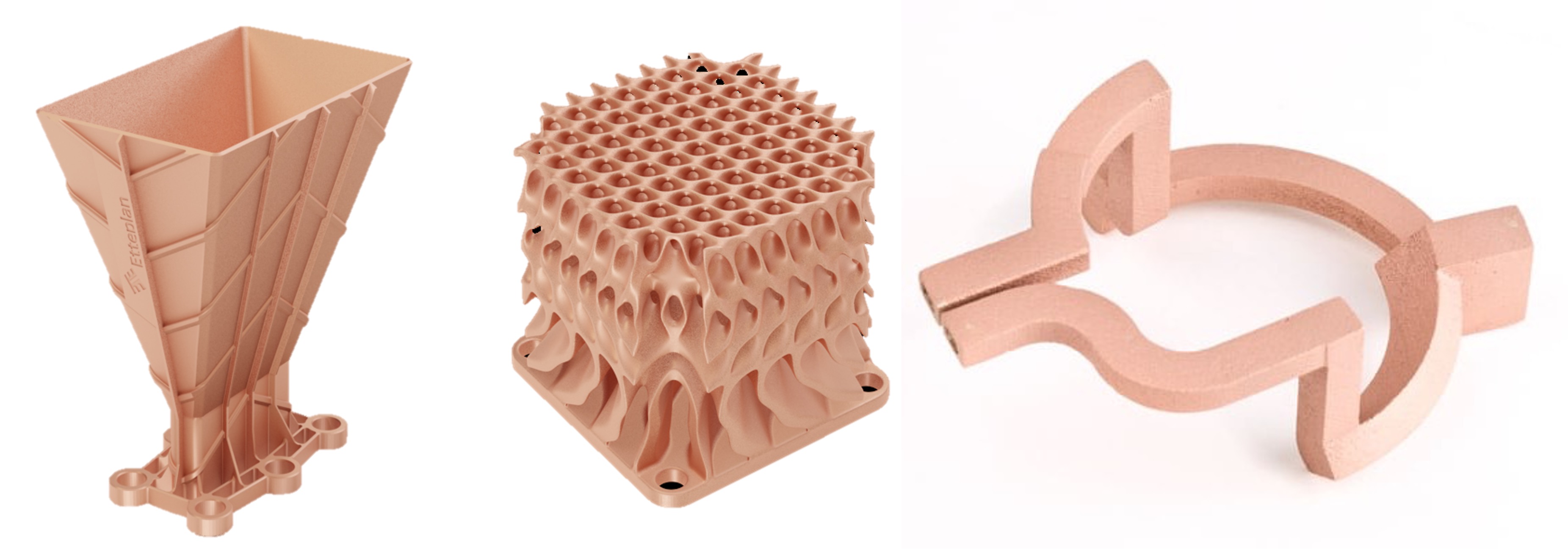

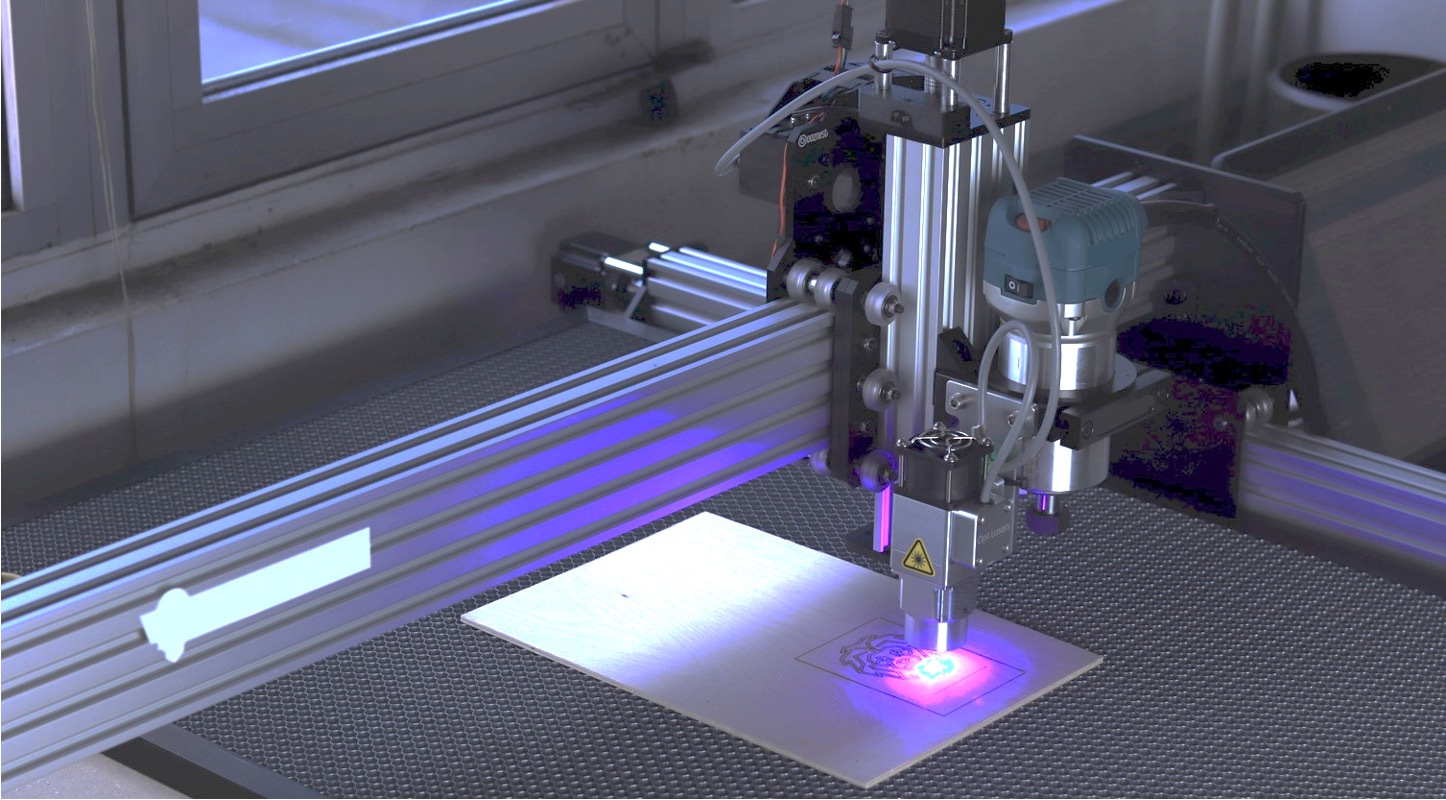

3D printing is the additive manufacturing technology where the part is created by adding material layer by layer. 3D printing could be used for making prototypes, low volume production, functional prototypes etc applications across diverse sets of industries. 3D printing is available for both plastics and metals.

Below we’ll discuss the factors which influence the selection of manufacturing technology.

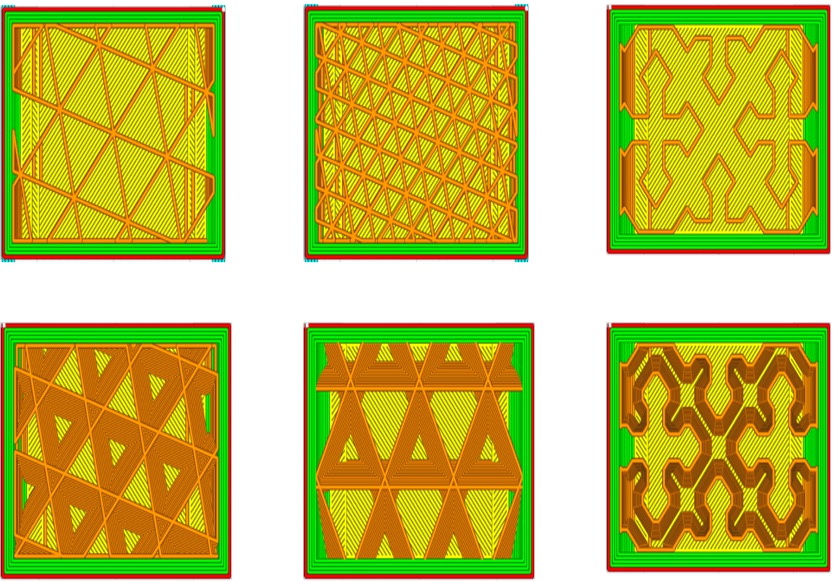

Complexity

Higher design complexity will lead to longer setup times and extra cost. Instead, the designer should opt for 3D printing, if precision and strength are not key, which costs significantly lower and fast turnaround. For less complex parts, CNC is a good and cost-effective option than 3D printing.

Precision tolerances

If close tolerances are the key, then CNC is the best option. Only CNC machining will be able to produce parts matching precise tolerances. No other conventional manufacturing technology can achieve that.

Turnaround time

For faster turnaround, 3D printing is the best option for high complexity design. However, due to the size limitations of 3Dprinting, parts could be 3D printed in separated pieces and joined later. Additional time is needed to re-assemble the printed parts. On the other hand, larger parts could be CNC machined in a single piece saving extra rework time. However, CNC machining turnaround time could also be affected if additional set-ups are needed to hold complex design and post-processing for physical properties enhancement.

Part strength

CNC machining largely retains the internal structure of the machined part maintaining the strength & rigidity. On the other hand, 3D printing creates parts layer by layer with hollow internal structures. This reduces the strength of the part. A designer could use the mix of both CNC machined and 3D printed parts to optimize the design without compromising the strength and integrity of the design. This mixed mode is going to be the preferred choice of the designers where they could leverage the best of the conventional and additive manufacturing process.

Materials

Both CNC and 3D printing can make parts across a wide range of materials. Material selection depends upon the nature of the application. Certain 3D printing processes (dual-nozzle) could create multi-material or composite material prints that are lighter in weight but higher in strength. Means higher strength to weight ratio. This type of multi-material printing has found scope especially in automotive and aerospace applications where strength to weight ratio is key to enhance performance e.g reduced fuel burn.

Waste generation

CNC machining generated a lot of waste material due to the subtractive type process where the material is removed gradually to create the part. However, very little waste is generated from 3D printing in the form of supports required to create overhang features. One start-up molyworks is recycling the metal waste generated across the manufacturing industries into powder form thru their patented technology as a feedstock for AM. This will not only lower the cost of AM made parts but also promote sustainable manufacturing.

Conclusion

AM has made rapid strides in recent years with claims that AM will take over conventional manufacturing sooner or later. However, Conventional manufacturing and additive manufacturing will co-exist till the time AM becomes mature enough to directly challenge the CM enabled economies of scale.

Blog created by - 3D SculpLab Team

3D SculpLab

3D SculpLab