Materials

Wide material options for your requirements

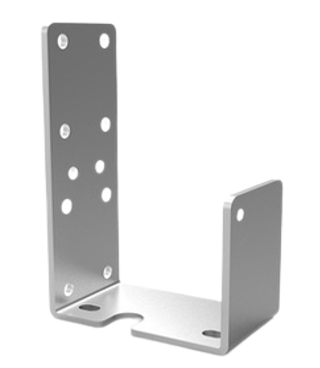

Sheet Metal

Mild Steel 1018

AISI 1018 mild/low carbon steel has excellent weldability, produces a uniform and harder case and it is considered the best steel for carburized parts. AISI 1018 mild/low carbon steel offers a good balance of toughness, strength, and ductility. It produces exceptional welds that do not require pre- or post-heating processes. 1018 responds well to case hardening and heat treating.

General Characteristics -

- Excellent weldability

- Tough & ductile

Common Applications -

- Mounting brackets

- Welded assembly of multi-components

Material properties -

| Modulus of elasticity / Young Mod. | 200 GPa |

| Yield Strength | 370 MPa |

| Ultimate Tensile strength | 440 MPa |

| Elongation at break | 15% |

| Hardness | 71 HRB |

| Thermal expansion coefficient | 12.1 µm/m-°C |

| Thermal conductivity | 51.9 W/m-°C |

| Electrical resistivity | 15.9 μΩ-cm |

| Corrosion | Poor Resistance |

| Welding | High weldability |

Post-processing -

- Not suitable for anodizing

Other information -

| Price | TBD |

| Lead Time | 2~3 weeks |

| Max part size | 200x200x200mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Stainless Steel 304

Stainless Steel 304

Stainless steel 304 It is the most versatile and most widely used stainless steel available and has excellent forming and welding characteristics. SS 304 can be readily braked or roll-formed into a variety of components for applications in the industrial, architectural, and transportation fields. Post-weld annealing is not required when welding thin sections.

General Characteristics -

- Excellent corrosion resistance

- Excellent weldability

Common Applications -

- Mounting brackets

- Food processing equipment

- Welded assembly of multi-components

Material properties -

| Modulus of elasticity / Young Mod. | 195 GPa |

| Yield Strength | 240 MPa |

| Ultimate Tensile strength | 585 MPa |

| Elongation at break | 50% |

| Hardness | 80 HRB |

| Max Working temp. | 925˚C |

| Thermal expansion coefficient | 17.3 µm/m-°C |

| Thermal conductivity | 15.2 W/m-°C |

| Electrical resistivity | 72 μΩ-cm |

Other information -

| Price | TBD |

| Lead Time | 2~3 weeks |

| Max part size | 300x300x300mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Stainless Steel 316L

Stainless Steel 316L

Stainless steel 316 is the standard molybdenum-bearing grade, second in importance to 304 amongst the austenitic stainless steels. The molybdenum gives 316 better overall corrosion resistant properties than Grade 304, particularly higher resistance to pitting and crevice corrosion in chloride environments. 316L stainless steel offers higher creep, stress to rupture, and tensile strength at elevated temperatures.

General characteristics -

- Excellent weldability

- High tensile strength

- High creep resistance

- Excellent corrosion resistance

Common Application -

- Fasteners

- Pharmaceuticals

- Marine applications

- Architectural applications

Material properties -

| Modulus of elasticity / Young Mod. | 193 GPa |

| Yield Strength | 170 MPa |

| Ultimate Tensile strength | 485 MPa |

| Elongation at break | 40% |

| Hardness | 95 HRB |

| Thermal expansion coefficient | 15.9 µm/m-°C |

| Thermal conductivity | 16.3 W/m-°C |

| Electrical resistivity | 74 μΩ-cm |

| Corrosion | High Resistance |

| Welding | Excellent weldability |

Post-processing -

- Hot & cold working

- Annealing

Other information -

| Price | TBD |

| Lead Time | 2~3 weeks |

| Max part size | 200x200x200mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

3D SculpLab

3D SculpLab