Materials

Wide material options for your requirements

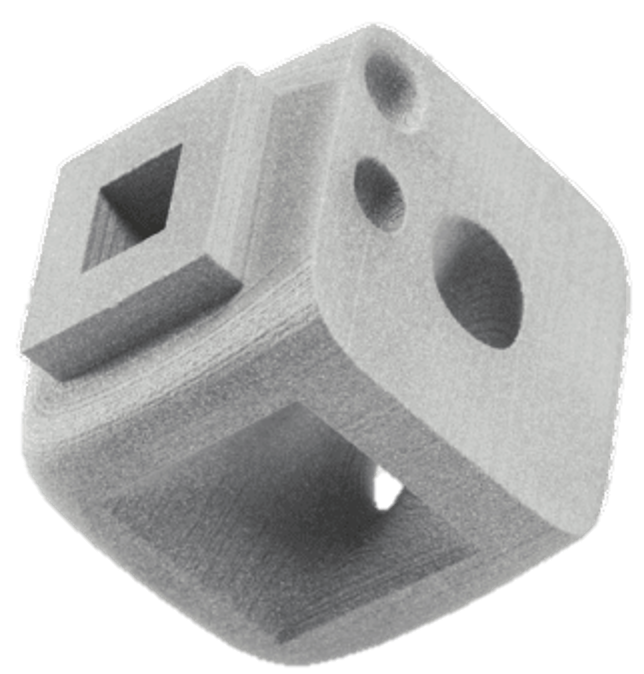

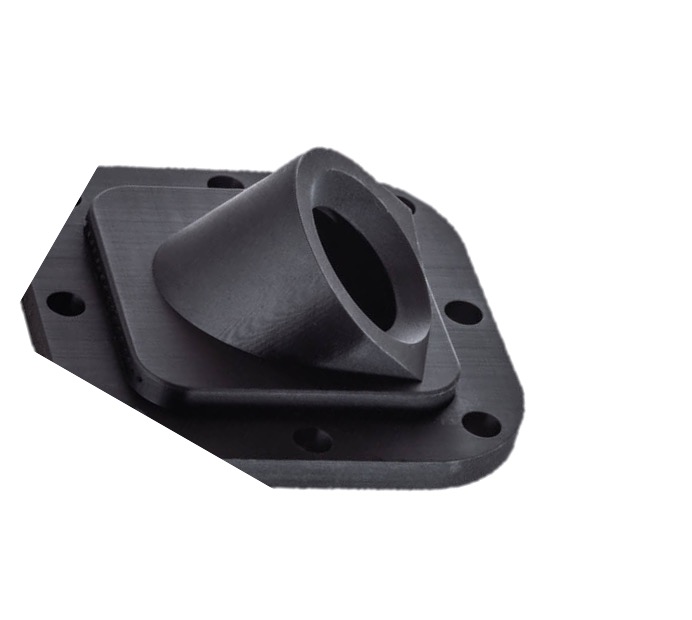

3D Printing

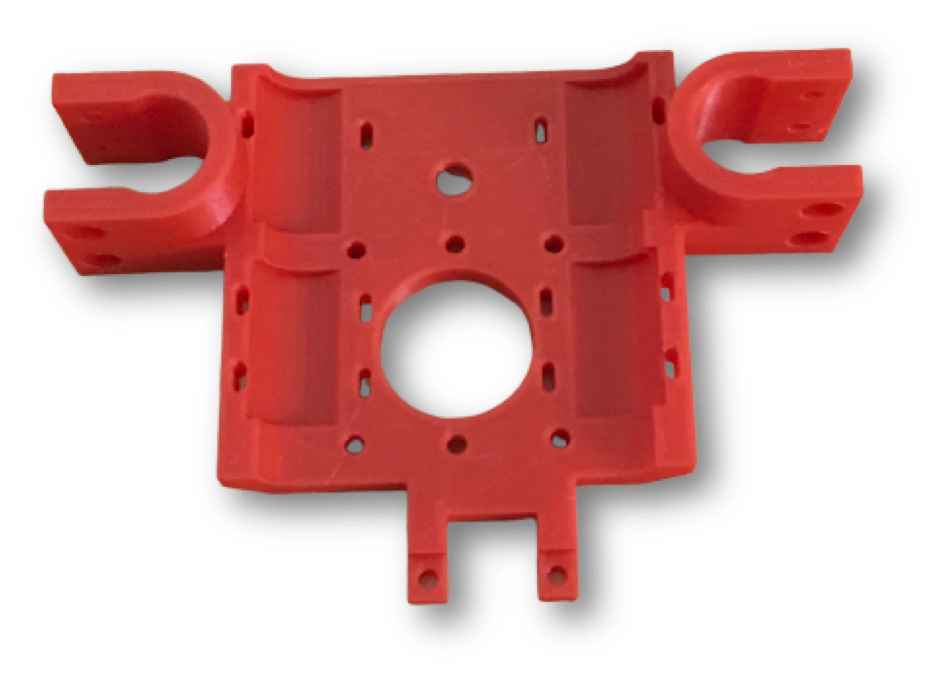

FDM - PLA

Key features -

- PLA (Polylactic Acid)

- Ideal for general models and prototypes

- Good tensile strength

- Bio-degradable

- Low cost

Mechanical properties -

| Tensile modulus | 2346 MPa |

| Tensile stress at yield | 38 MPa |

| Tensile stress at break | 36 MPa |

| Elongation at yield | 2.10% |

| Elongation at break | 2.84% |

| Flexural strength | 65.7 MPa |

| Flexural modulus | 2409 MPa |

| Hardness | 83 Shore D |

Thermal properties -

| Max Working temp. | Upto 60˚C |

Other info -

| Price | TBD |

| Lead Time | ~2 days |

| Min. Wall Thickness (Recommended) | 1.2 mm |

| Tolerances | ±0.5mm |

| Max part size | 300x300x300mm |

| Layer height | 100 - 250 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

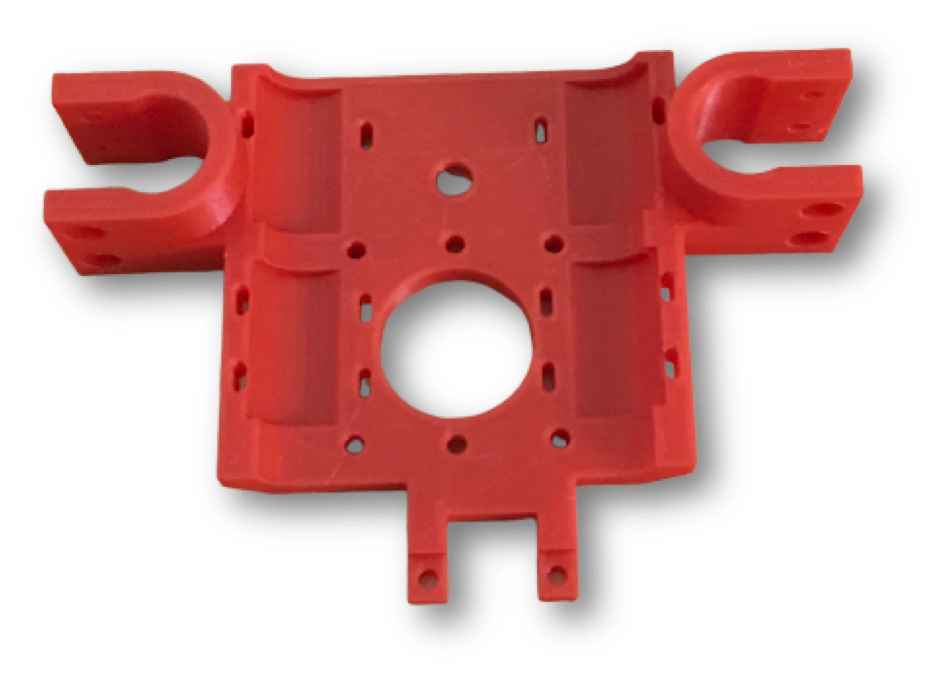

FDM - Tough PLA

FDM - Tough PLA

Key features -

- High Strength than PLA

- Higher stiffness compared with ABS

- More reliable than ABS for larger prints

Mechanical properties -

| Tensile modulus | 1820 MPa |

| Tensile stress at yield | 37 MPa |

| Tensile stress at break | 37 MPa |

| Elongation at yield | 3.10% |

| Elongation at break | 3.10% |

| Flexural strength | 78 MPa |

| Flexural modulus | 2490 MPa |

| Hardness | 79 Shore D |

Thermal properties -

| Max Working temp. | Upto 60˚C |

Other info -

| Price | TBD |

| Lead Time | ~2 days |

| Min. Wall Thickness (Recommended) | 1.2 mm |

| Tolerances | ±0.5mm |

| Max part size | 200x200x200mm |

| Layer height | 100 - 250 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

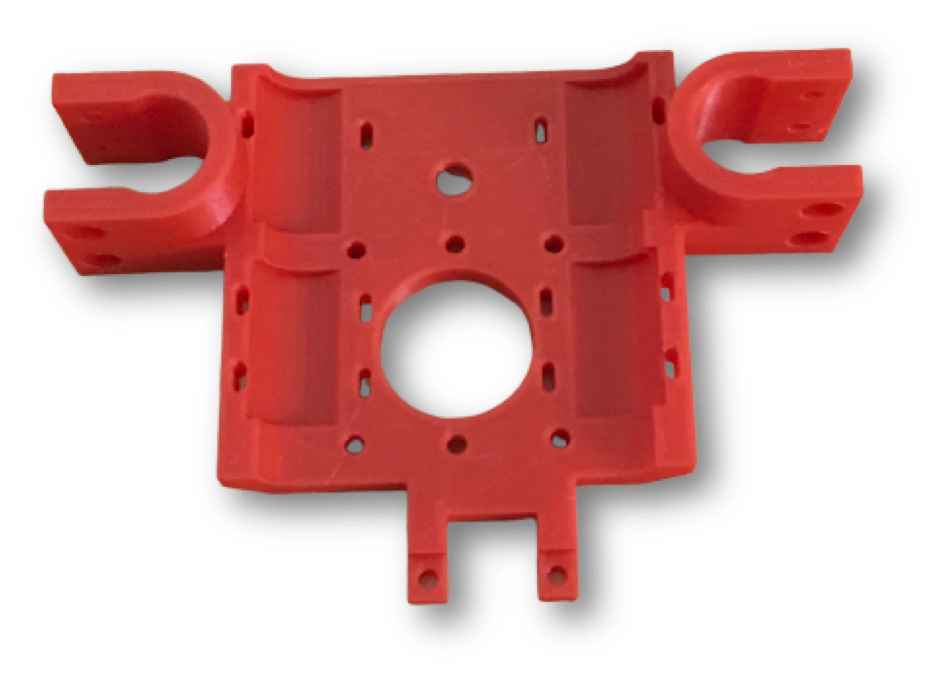

FDM - ABS

FDM - ABS

Key features -

- Used for functional prototypes.

- High strength and durability.

- Excellent mechanical properties.

- Great for strong prototypes or end-use parts.

Mechanical properties -

| Tensile modulus | 1681 MPa |

| Tensile stress at yield | 39 MPa |

| Tensile stress at break | 33 MPa |

| Elongation at yield | 3.50% |

| Elongation at break | 4.80% |

| Flexural strength | 70 MPa |

| Flexural modulus | 2070 MPa |

| Hardness | 76 Shore D |

Thermal properties -

| Max Working temp. | Upto 85˚C |

Other info -

| Price | TBD |

| Lead Time | ~2 days |

| Min. Wall Thickness (Recommended) | 1.2 mm |

| Tolerances | ±0.5mm |

| Max part size | 200x200x200mm |

| Layer height | 100 - 250 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

FDM - Polycarbonate

FDM - Polycarbonate

Key features -

- High toughness

- Dimensionally stable

- Flame retardant properties

- Resists temperatures upto 110ºC

Mechanical properties -

| Tensile modulus | 1904 MPa |

| Tensile stress at break | 53.7 MPa |

| Elongation at break | 5.90% |

| Flexural strength | 95 MPa |

| Flexural modulus | 2310 MPa |

| Hardness | 80 Shore D |

Thermal properties -

| Max Working temp. | Upto 110˚C |

Other info -

| Price | TBD |

| Lead Time | ~2 days |

| Min. Wall Thickness (Recommended) | 1.2 mm |

| Tolerances | ±0.5mm |

| Max part size | 200x200x200mm |

| Layer height | 100 - 250 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

FDM - PETG

FDM - PETG

Key features -

- Excellent chemical resistance.

- Tough & dimensionally stable.

- Ideal for short-run mfg & functional prototypes.

Mechanical properties -

| Tensile modulus | 1537 MPa |

| Tensile stress at yield | 41 MPa |

| Tensile stress at break | 37.7 MPa |

| Elongation at yield | 4.70% |

| Elongation at break | 5.10% |

| Flexural strength | 79 MPa |

| Flexural modulus | 1990 MPa |

| Hardness | 72 Shore D |

Thermal properties -

| Max Working temp. | Upto 70˚C |

Other info -

| Price | TBD |

| Lead Time | ~2 days |

| Min. Wall Thickness (Recommended) | 1.2 mm |

| Tolerances | ±0.5mm |

| Max part size | 200x200x200mm |

| Layer height | 100 - 250 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

FDM - TPU

FDM - TPU

Key features -

- Semi-flexible

- Chemically resistant

- High impact strength

- Resistance to wear and tear

Mechanical properties -

| Tensile modulus | 26 MPa |

| Tensile stress at yield | 8.6 MPa |

| Tensile stress at break | 39 MPa |

| Elongation at yield | 55% |

| Elongation at break | 580% |

| Flexural strength | 4.3 MPa |

| Flexural modulus | 78.7 MPa |

| Hardness | 95 Shore D |

Thermal properties -

| Max Working temp. | Upto 100˚C |

Other info -

| Price | TBD |

| Lead Time | ~2 days |

| Min. Wall Thickness (Recommended) | 1.2 mm |

| Tolerances | ±0.5mm |

| Max part size | 200x200x200mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

FDM - PolyPropylene

FDM - PolyPropylene

Key features -

- High toughness

- Fatigue resistance

- Retains its shape after bending & flexing

- Recyclable

Mechanical properties -

| Tensile modulus | 220 MPa |

| Tensile stress at yield | 8.7 MPa |

| Elongation at yield | 18% |

| Elongation at break | >300% |

| Flexural strength | 13 MPa |

| Flexural modulus | 305 MPa |

| Hardness | 45 Shore D |

Thermal properties -

| Max Working temp. | Upto 105˚C |

Other info -

| Price | TBD |

| Lead Time | ~2 days |

| Min. Wall Thickness (Recommended) | 1.2 mm |

| Tolerances | ±0.5mm |

| Max part size | 200x200x200mm |

| Layer height | 100 - 250 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

FDM - Soft FLEX

FDM - Soft FLEX

Key features -

- Highly flexible.

- Suitable for applications where flexibility is key

Mechanical properties -

| Elongation at break | 6% |

| Flexural strength | 41 MPa |

| Hardness | 46 Shore D |

Thermal properties -

| Max Working temp. | Upto 60˚C |

Other info -

| Price | TBD |

| Lead Time | ~2 days |

| Min. Wall Thickness (Recommended) | 1.2 mm |

| Tolerances | ±0.5mm |

| Max part size | 200x200x200mm |

| Layer height | 100 - 250 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

FDM - Nylon

FDM - Nylon

Nylon is a non-abrasive material that is good for ergonomic shapes and holding fixtures for parts that are easily scratched. It can be painted or dyed.

Key features

- Low friction coefficient

- Impact and abrasion-resistant

Mechanical properties

| Tensile modulus (Young Mod) | 1.7 GPa |

| Tensile stress at yield | 51 MPa |

| Tensile stress at break | 36 MPa |

| Elongation at break | 150% |

| Flexural strength | 50 MPa |

| Flexural modulus | 1.4 GPa |

| Izod Impact - notched (J/m) | 110 J/m |

| Density | 1.1 g/cm3 |

Thermal properties -

| Max Working temp. | Upto 60˚C |

Other information

| Price | TBD |

| Lead Time | 2~3 days |

| Min. Wall Thickness (Recommended) | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 200x200x200mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

FDM - Tear Support

FDM - Tear Support

Key features -

- Support material

- Does not cause support marks

- Please contact us for more information

SLA - Tough (ABS Like)

SLA - Tough (ABS Like)

Key features -

- Strength of ABS

- Minimal deflection

- Stiff & strong parts

- High-quality surface finish

Mechanical properties -

| Tensile modulus | 2290 MPa |

| Tensile stress at break | 46 MPa |

| Elongation at break | 8% |

| Flexural strength | 74 MPa |

| Flexural modulus | 2040 MPa |

| Hardness | 86 Shore D |

Thermal properties -

| Max Working temp. | Upto 60˚C |

Other info -

| Price | TBD |

| Lead Time | ~2 days |

| Min. Wall Thickness (Recommended) | 0.8 mm |

| Tolerances | ±0.5mm |

| Max part size | 145x145x175mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

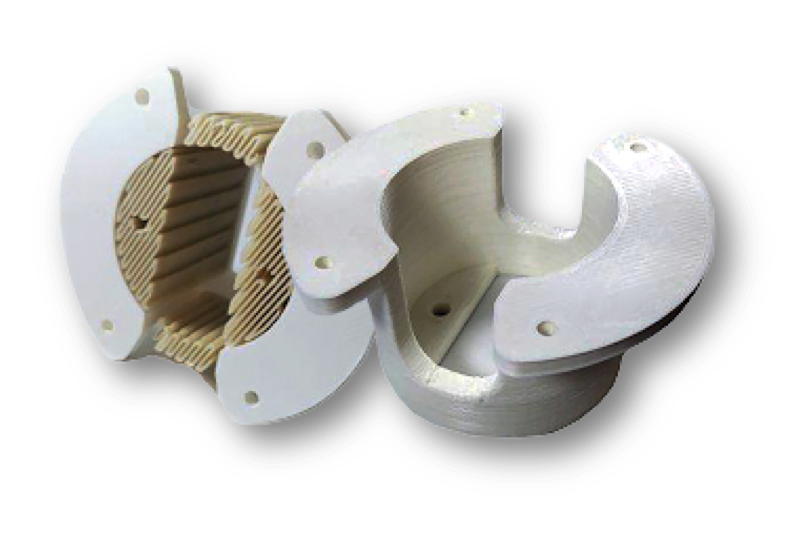

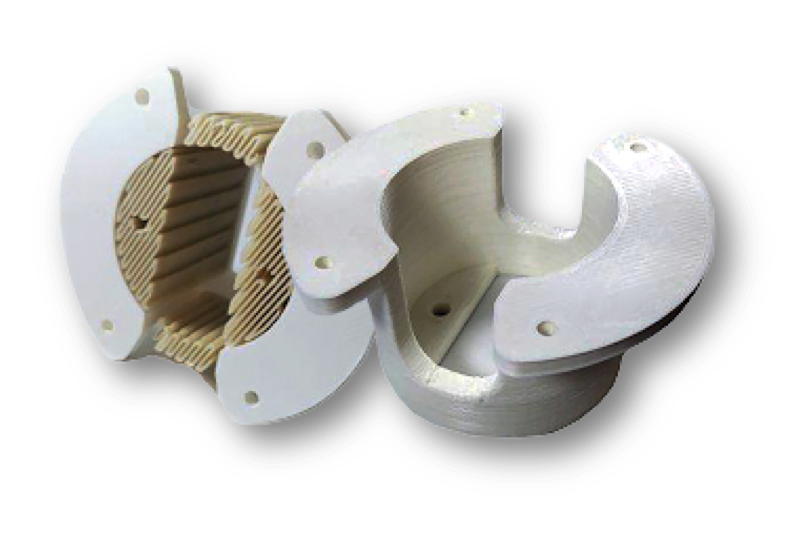

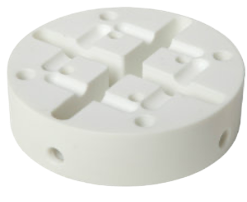

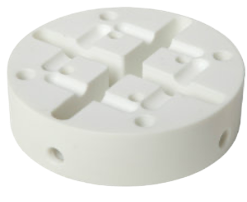

SLS - Nylon 12

SLS - Nylon 12

Key properties -

- Nylon has excellent strength

- Withstands higher temperatures

- High friction resistance & stiffness

Mechanical properties -

| Tensile modulus | 1650 MPa |

| Tensile strength | 48 Mpa |

| Elongation at break | 18% |

| Flexural strength | 41 Mpa |

| Flexural modulus | 1500 Mpa |

| Hardness | 75 Shore D |

| Heat deflection temp (Td) | 86˚C |

Other information -

| Lead Time | ~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 300×300×500mm |

| Layer height | 150 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

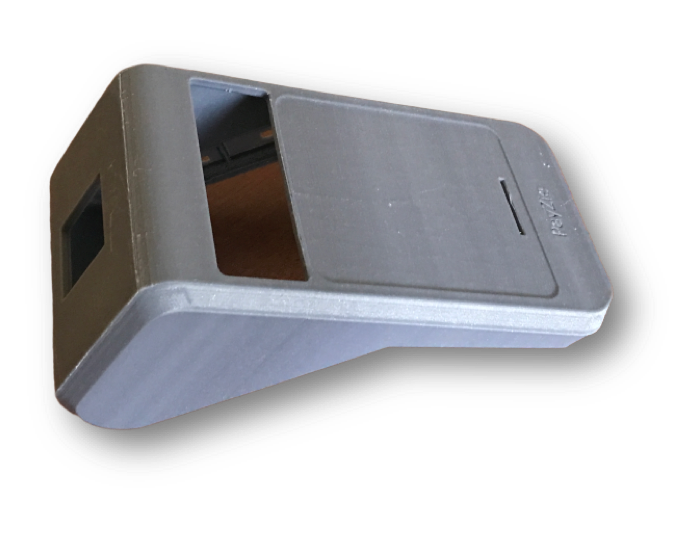

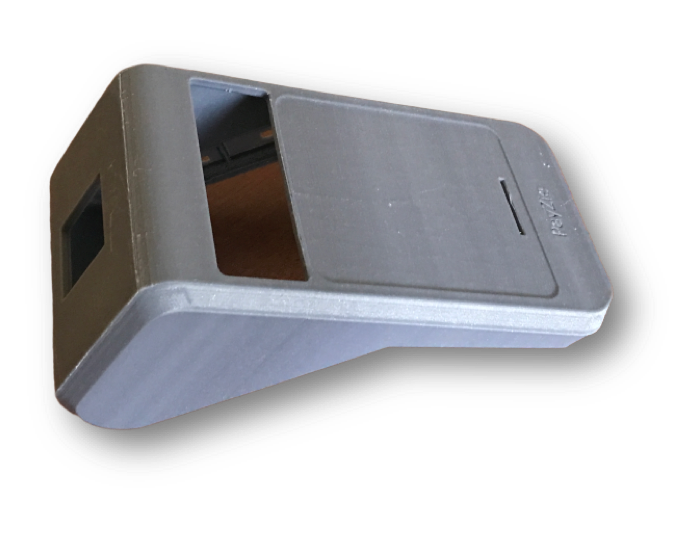

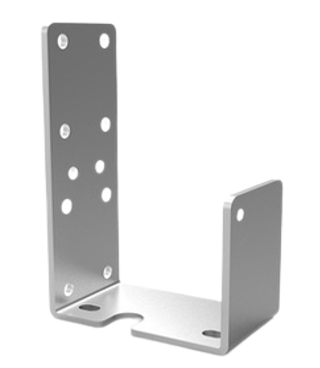

Aluminum

Aluminum

Aluminum (AlSi10Mg) is a typical casting alloy with good casting properties and is typically used for cast parts with thin walls and complex geometry. It offers good strength, hardness and dynamic properties and is therefore also used for parts subject to high loads. Aluminium AlSi10Mg is ideal for applications that require a combination of good thermal properties and low weight. They can be machined, spark-eroded, welded, micro shot-peened, polished and coated if required.

General characteristics -

- Low weight

- Good thermal properties

Common application -

- Weight reduction

- Automotive industry

- Prototyping

Mechanical Properties -

| Tensile modulus | 70 GPa (x-y-z dir.) |

| Tensile strength | 390 MPa (x-y dir.) & 390MPa (z dir.) |

| Tensile stress at yield | 220 MPa (x-y dir.) & 210MPa (z dir.) |

| Elongation at break | 8% (x-y dir.) & 6% (z dir.) |

Post-processing -

- Machining

- Polishing

- Coating

Other info -

| Price | TBD |

| Lead Time | 3~4 days |

| Wall Thickness | 1mm |

| Tolerances | See below |

| Max part size | 250×250×300mm |

| Layer height | 100 microns |

Accuracy :

- +/- 0.2 to +/- 0.3mm for parts of overall size up to 50mm,

- +/- 0.3 to +/- 0.4mm for parts of overall size up to 150mm

- +/- 0.4 to +/- 0.5mm for parts of overall size up to 250mm.

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

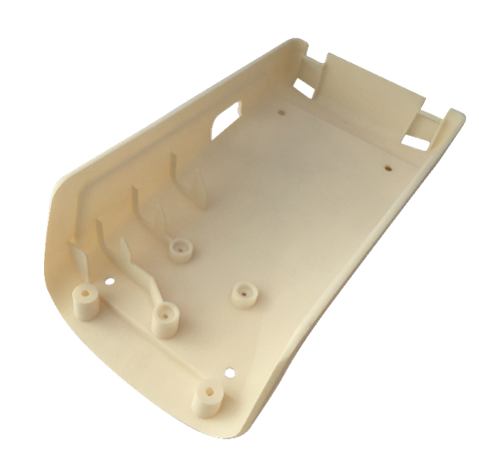

FDM - ABS-M30

FDM - ABS-M30

ABS-M30 is stronger than standard ABS, making it ideal for prototyping, concept evaluation, functional parts, manufacturing aids etc.

General Characteristics -

- High strength than standard ABS

- High toughness

- Lightweight

Common Applications -

- Functional prototypes

- Jigs and fixtures

- Short-run production

Mechanical properties -

| Tensile modulus | 2.4 GPa |

| Tensile stress at yield | 30 MPa |

| Tensile stress at break | 28 MPa |

| Elongation at yield | 1.80% |

| Elongation at break | 8% |

| Flexural modulus | 2.2GPa |

Other info -

| Price | TBD |

| Lead Time | 2~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 400x350x400 |

| Layer height | 150 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

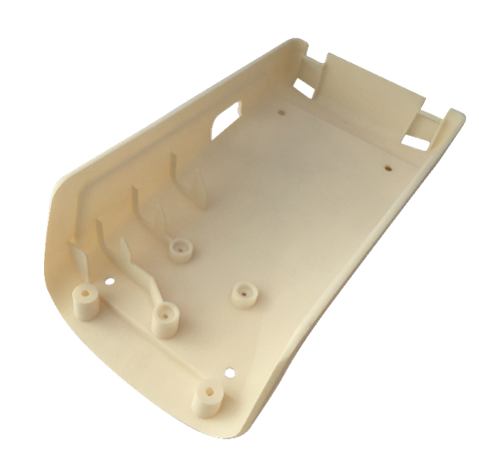

FDM - ASA(UV Resist)

FDM - ASA(UV Resist)

ASA (Acrylonitrile Styrene Acrylate). It is similar to ABS but with better UV resistance, mechanical properties and aesthetics than ABS. ASA is suitable for general-purpose prototyping, jigs and fixtures, short-run production parts and outdoor applications.

General Characteristics -

- Higher UV resistance

- Better aesthetics

Common Applications -

- Prototyping

- Functional part

- Jigs and fixture

- Outdoor applications

Mechanical properties -

| Tensile modulus | 2.14GPa |

| Tensile stress at yield | 32MPa |

| Tensile stress at break | 31MPa |

| Elongation at yield | 2.50% |

| Elongation at break | 5.90% |

| Flexural modulus | 1.98GPa |

Other info -

| Price | TBD |

| Lead Time | 2~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 400x350x400 |

| Layer height | 150 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

SLA - Accura 25(PP like)

SLA - Accura 25(PP like)

Accura 25 (another name VisiJet® SL Flex) provides the polypropylene-like look and feel and white opaque colour with high flexibility. The part retains its shape and is generally suitable for snap-fits assemblies.

General Characteristics -

- High flexibility

- Shape retention

Common Applications -

- Snap-fit assemblies

- General prototyping

- Functional parts

Mechanical properties -

| Tensile modulus | 1.6GPa |

| Tensile strength | 38MPa |

| Elongation at break | 16% |

| Flexural strength | 57MPa |

| Flexural modulus | 1.4GPa |

| Hardness | 80 Shore D |

| Heat deflection temp (Td) | 60˚C |

Other info -

| Price | TBD |

| Lead Time | ~2 days |

| Wall Thickness | 0.5mm |

| Tolerances | ±0.1mm |

| Max part size | 380x380x250mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

SLA - Fig4(PC like)

SLA - Fig4(PC like)

Rigid material (Figure 4® PRO-BLK) is a high precision resin producing parts with a smooth surface finish and sidewall quality and has excellent mechanical properties.

General Characteristics -

- Excellent mechanical properties

- Good surface finish

Common Applications -

- Electrical housings

- Connectors

- General use parts

Mechanical properties -

| Tensile modulus | 2.3GPa |

| Tensile strength | 63MPa |

| Tensile stress at yield | 63MPa |

| Elongation at yield | 4.70% |

| Elongation at break | 12% |

| Flexural strength | 92MPa |

| Flexural modulus | 2.2GPa |

| Hardness | 79 Shore D |

| Heat deflection temp (Td) | 70˚C |

Other info -

| Price | TBD |

| Lead Time | ~2 days |

| Wall Thickness | 0.5mm |

| Tolerances | ±0.1mm |

| Max part size | 124x70x196mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Titanium

Titanium

Titanium (Ti6Al4V) has an excellent strength to weight ratio that makes it the right choice where lightweight loading structures are needed. It is also biocompatible, so can be used across a wide range of surgical and dental applications. It has good corrosion resistance.

General characteristics

- High specific strength

- High corrosion resistance

- Excellent biocompatibility

- Good osseointegration

- Low thermal expansion

- Low thermal conductivity

Common applications

- Medical and dental

- Aerospace and defence

- Motorsport

- Jewellery and art

- Maritime applications

- High-end sports equipment

Mechanical properties

| Tensile modulus (Young Mod) | 132 GPa (x-y dir.) & 128 GPa (z dir.) |

| Tensile strength (UTM) | 1091 MPa (x-y dir.) & 1084 MPa (z dir.) |

| Tensile stress at yield | 1020 MPa (x-y dir.) & 987 MPa (z dir.) |

| Elongation at break | 16% (x-y dir.) & 17% (z dir.) |

| Hardness | 363 Vickers |

| Melting temperature | 1635˚C |

| Thermal conductivity | 6 W/mK to 8 W/mK |

| Thermal expansion coefficient | 8x10-6 K-1 to 9x10-6 K-1 |

| Density | 4.42 g/cm3 |

Post-processing

- Machining

- Polishing

- Coating

Other info

| Price | TBD |

| Lead Time | 3~4 days |

| Wall Thickness | 0.5mm |

| Tolerances | See below |

| Max part size | 250×250×300mm |

| Layer height | 100 microns |

Accuracy

- +/- 0.2 to +/- 0.3mm for parts of overall size up to 50mm

- +/- 0.3 to +/- 0.4mm for parts of overall size up to 150mm

- +/- 0.4 to +/- 0.5mm for parts of overall size up to 250mm

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Onyx (Strong Nylon)

Onyx (Strong Nylon)

Onyx (Strong Nylon) is a micro carbon fibre-filled nylon that yields accurate parts with a near-flawless surface finish. It offers high strength, toughness, and chemical resistance. Additional strength can also be achieved by reinforcing it with fibres like carbon fiber, glass fiber, HSHT Glass fiber & kevlar to yield aluminium-strength parts.

General Characteristics

- High strength

- Toughness

- Chemical resistance

Common Applications

- Plastic Part Replacement

- Housings

- Sensor Mounts

- Prototypes

Mechanical properties

| Tensile modulus (Young's Mod) | 2.4 GPa |

| Tensile stress at yield | 40 MPa |

| Tensile stress at break | 37 MPa |

| Elongation at break | 25% |

| Flexural strength | 71 MPa |

| Flexural modulus | 3 GPa |

| Izod Impact - notched | 330 J/m |

| Heat deflection temp (Td) | 145˚C |

| Density | 1.2 g/cm3 |

Other information

| Price | TBD |

| Lead Time | 2~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 330×270×200mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

OnyxFR (Flame Resist)

OnyxFR (Flame Resist)

Onyx FR is a flame-retardant variant of Onyx(strong nylon) designed for use in applications where parts must be non-flammable. Additional strength can also be achieved by reinforcing it with fibers like carbon fiber, glass fiber, HSHT Glass fiber & kevlar to yield aluminium-strength parts.

General Characteristics

- High strength

- Toughness

- Chemical resistance

Common Applications

- Welding fixture

- Aerospace clips & brackets

- Automobile industry

- Laser marking fixtures

- Electrical/electronic brackets

- Enclosures & fixtures

Mechanical Properties

| Tensile modulus (Young Mod) | 3.0 GPa |

| Tensile stress at yield | 41 MPa |

| Tensile stress at break | 40 MPa |

| Elongation at break | 18% |

| Flexural strength | 71 MPa |

| Flexural modulus | 3.6 GPa |

| Heat deflection temp (Td) | 145˚C |

| Density | 1.2 g/cm3 |

Other information

| Price | TBD |

| Lead Time | 2~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 330×270×200mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Onyx ESD

Onyx ESD

Onyx ESD is a static-dissipative with micro carbon fibre-filled nylon material, precision-engineered for a tight range of surface resistance. Onyx ESD meets ESD-safe requirements of the most stringent manufacturing needs. Onyx ESD is stronger and stiffer than Onyx(Strong Nylon), with the same near-perfect surface finish, making it suitable for advanced manufacturing applications from electronics assembly, industrial robotics and process automation.

General Characteristics

- Higher stiffness

- Higher-strength

- Good surface finish

Common Applications

- Robotics

- Electrical mountings/enclosures

- Electronics mountings/enclosures

- Aerospace and automotive industries

Mechanical Properties

| Tensile modulus (Young Mod) | 4.2 GPa |

| Tensile stress at yield | 52 MPa |

| Tensile stress at break | 50 MPa |

| Elongation at break | 25% |

| Flexural strength | 83 MPa |

| Flexural modulus | 3.7 GPa |

| Izod Impact - notched (J/m) | 44 J/m |

| Heat deflection temp (Td) | 138˚C |

| Density | 1.2 g/cm3 |

Other Information

| Price | TBD |

| Lead Time | 2~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 330×270×200mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Carbon Fiber

Carbon Fiber

Carbon Fiber is a unique, ultra-high-strength material when laid into a base material like Onyx(Strong Nylon), it can create parts as strong as 6061-T6 Aluminum or even substitute it. It’s extremely stiff and strong and can be laid down in a wide variety of geometries.

General Characteristics

- Extremely stiff and strong

Common Applications

- High-strength tools & fixtures

- Brackets & mounts

- CMM/inspection fixturing

- End-use parts

- Functional prototype

Mechanical Properties

| Tensile Strength | 800 MPa |

| Tensile Modulus | 60 GPa |

| Tensile Strain at Break | 1.50% |

| Flexural Strength | 540 MPa |

| Flexural Modulus | 51 GPa |

| Flexural Strain at Break | 1.20% |

| Compressive Strength | 420 MPa |

| Compressive Modulus | 62 GPa |

| Compressive Strain at Break | 0.70% |

| Heat Deflection Temp | 105˚C |

| Izod Impact - notched | 960 J/m |

| Density | 1.4 g/cm3 |

Other Information

| Price | TBD |

| Lead Time | 2~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 330×270×200mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Glass Fiber

Glass Fiber

GlassFiber is an entry-level fiber material capable of producing parts 10x stronger than ABS when laid into a base material like Onyx(Strong Nylon). Glass fiber provides a more affordable alternative to carbon fiber. Glass fiber reinforcement results in stronger and more robust tools.

General Characteristics

- 10x stronger than ABS

- More affordable than carbon fiber

Common Applications

- Soft jaws

- medium-strength tooling

- Insulation reinforcement

- hand tools

Mechanical Properties

| Tensile Strength | 590 MPa |

| Tensile Modulus | 21 GPa |

| Tensile Strain at Break | 3.80% |

| Flexural Strength | 200 MPa |

| Flexural Modulus | 22 GPa |

| Flexural Strain at Break | 1.10% |

| Compressive Strength | 180 MPa |

| Compressive Modulus | 24 GPa |

| Heat Deflection Temp | 105˚C |

| Izod Impact - notched | 2600 J/m |

| Density | 1.5 g/cm3 |

Other Information

| Price | TBD |

| Lead Time | 2~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 330×270×200mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Glass Fiber (HSHT)

Glass Fiber (HSHT)

High Strength High Temperature (HSHT) glass fiber has high strength and retains strength in high temperatures environments. Not as stiff as carbon fiber but Onyx(strong nylon) parts reinforced with HSHT are strong in both low and high temperatures environments. Its strength is close to 6061-T6 Aluminum. HSHT reinforcement is best suited for parts in high-temperature environments like molds, autoclaves etc.

General Characteristics

- Retains strength at high and low temperature

Common Applications

- Polymer molds

- Low volume proto Injection Molds

- High-temperature Fixtures

- High-Temperature application prototypes

Mechanical Properties

| Tensile Strength | 600 MPa |

| Tensile Modulus | 21 GPa |

| Tensile Strain at Break | 3.90% |

| Flexural Strength | 420 MPa |

| Flexural Modulus | 21 GPa |

| Flexural Strain at Break | 2.20% |

| Compressive Strength | 216 MPa |

| Compressive Modulus | 21 GPa |

| Compressive Strain at Break | 0.80% |

| Heat Deflection Temp | 150˚C |

| Izod Impact - notched | 3100 J/m |

| Density | 1.5 g/cm3 |

Other Information

| Price | TBD |

| Lead Time | 2~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 330×270×200mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Kevlar

Kevlar

Kevlar based parts are known for their energy absorption and extreme toughness. When combined with Onyx(Strong Nylon) or another base material, it produces impact-resistant parts that are less prone to serious functional failure (fracture). Kevlar possesses excellent durability, making it optimal for parts that are subjected to repeated and sudden loading. As stiff as fiberglass and much more ductile, it can be used for a wide variety of applications.

General Characteristics

- High toughness

- Impact-resistant

- Excellent durability

Common Applications

- Tools

- Wear stops

- Part replacements

- Cradles & supports

Mechanical Properties

| Tensile Strength | 610 MPa |

| Tensile Modulus | 27 GPa |

| Tensile Strain at Break | 2.70% |

| Flexural Strength | 240 MPa |

| Flexural Modulus | 26 GPa |

| Flexural Strain at Break | 2.10% |

| Compressive Strength | 130 MPa |

| Compressive Modulus | 25 GPa |

| Compressive Strain at Break | 1.50% |

| Heat Deflection Temp | 105˚C |

| Izod Impact - notched | 2000 J/m |

| Density | 1.2 g/cm3 |

Other Information

| Price | TBD |

| Lead Time | 2~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 330×270×200mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

CF Nylon

CF Nylon

Carbon Fiber Nylon - Generic Nylon combined with carbon fiber creates extremely high-strength material. Carbon fiber reinforcement increases the strength of generic nylon exponentially. It’s extremely stiff and strong and can be laid down in a wide variety of geometries.

General Characteristics

- Extremely stiff and strong

Common Applications

- Plastic Part Replacement

- Housings

- Sensor Mounts

- Cosmetic Prototypes

Mechanical Properties

| ile Strength | 800 MPa |

| Tensile Modulus | 60 GPa |

| Tensile Strain at Break | 1.50% |

| Flexural Strength | 540 MPa |

| Flexural Modulus | 51 GPa |

| Flexural Strain at Break | 1.20% |

| Compressive Strength | 420 MPa |

| Compressive Modulus | 62 GPa |

| Compressive Strain at Break | 0.70% |

| Heat Deflection Temp | 105˚C |

| Izod Impact - notched | 960 J/m |

| Density | 1.4 g/cm3 |

Other Information

| Price | TBD |

| Lead Time | 2~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 330×270×200mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

GF Nylon

GF Nylon

Glass Fiber Nylon - Generic Nylon combined with glass fiber creates very high-strength material. Glass fiber reinforcement increases the strength of generic nylon immensely. It’s extremely stiff and strong and can be laid down in a wide variety of geometries. Also, it's a more cost-effective option than carbon fiber.

General Characteristics

- 10x strong than ABS

- More affordable than carbon fiber

Common Applications

- Soft jaws

- medium-strength tooling

- Insulation reinforcement

- hand tools

Mechanical Properties

| Tensile Strength | 590 MPa |

| Tensile Modulus | 21 GPa |

| Tensile Strain at Break | 3.80% |

| Flexural Strength | 200 MPa |

| Flexural Modulus | 22 GPa |

| Flexural Strain at Break | 1.10% |

| Compressive Strength | 180 MPa |

| Compressive Modulus | 24 GPa |

| Heat Deflection Temp | 105˚C |

| Izod Impact - notched | 2600 J/m |

| Density | 1.5 g/cm3 |

Other Information

| Price | TBD |

| Lead Time | 2~3 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 330×270×200mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Stainless Steel 17-4 PH

Stainless Steel 17-4 PH

Stainless Steel(17-4 PH) or SS630 is a multi-application material used for industrial uses. The density of 95% wrought strength. SS 17-4 PH enables you to make high-strength, robust metal parts for a wide variety of applications across the industrial spectrum.

General Characteristics

- High strength

- Robust parts

Common Applications

- End-of-Arm Tools

- Lightweight Brackets

- General High-Wear Tooling

- Functional Prototypes

- Custom Wrenches & Sockets

Mechanical Properties (FDM)

| Tensile modulus (Young Mod) | 140 GPa |

| Tensile strength (UTM) | 1050 MPa |

| Yield Strength | 800 MPa |

| Elongation at break | 5% |

| Hardness | 30 HRC |

| Density | 96% |

Other Information

| Price | TBD |

| Lead Time | 4~5 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 300×220×180mm |

| Layer height | 125 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Tool Steel H13

Tool Steel H13

Harder than 17-4 PH Stainless Steel and capable of maintaining material properties at high temperatures. TS H13 is an extremely versatile material to work with. Used for tool bodies, brazing fixtures, and other parts where hardness or heat resistance are required.

General Characteristics

- High strength

- High-temperature applications

Common Applications

- Cutting Tool Bodies

- Brazing Fixtures

- Mold Inserts

- Wear-Resistant Tools

- High-Strength Parts

Mechanical Properties (FDM)

| Tensile strength (UTM) | 1420 MPa |

| Yield Strength | 800 MPa |

| Elongation at break | 5% |

| Hardness | 40 HRC |

| Density | 94.50% |

Other Information

| Price | TBD |

| Lead Time | 4~5 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 300×220×180mm |

| Layer height | 125 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Tool Steel A2 & D2

Tool Steel A2 & D2

Tool Steel A2 and D2 are cold work tool steels defined by their extremely high hardness after heat treatment. A2 tool steel offers a combination of good wear resistance and high toughness. D2 tool steel is harder and more wear-resistant, but less tough. Both can be used for cutting and forming tools, or other applications where high hardness are valued.

General Characteristics

- Extremely hard

- Good wear resistance

Common Applications

- Punch Dies

- Forming Tools

- Stamping Dies

Mechanical Properties (FDM)

| Tool Steel A2 | Tool Steel D2 | |

| Tensile modulus (Young Mod) | 160 GPa | 187 GPa |

| Compressive yield strength | 1170 MPa | 1690 MPa |

| Hardness | 50 HRC | 55 HRC |

| Density | 94.50% | 97.00% |

Other Information

| Price | TBD |

| Lead Time | 4~5 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 300×220×180mm |

| Layer height | 125 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Inconel

Inconel

Inconel is a nickel-chromium-based superalloy that is extremely resistant to corrosion and strong at high temperatures. Can fabricate functional prototypes and end-use parts designed for harsh environments.

General Characteristics

- High corrosion resistance

- Retains strength at high temperature

Common Applications

- High-temperature fixtures

- Corrosion-resistant fittings

- Crucibles, Turbine hardware

Mechanical Properties

| Inconel 625(FDM) | Inconel 625 | Inconel 718 | |

| Tensile strength (UTM) | 765 MPa | 1000 MPa | 1241 MPa |

| Yield Strength | 334 MPa | 680 MPa | 1034 MPa |

| Elongation at break | 42% | 34% | 12% |

| Hardness | 7 HRC | 27 HRC | 47 HRC |

| Density | 96.50% | 98.00% | 98.00% |

Accuracy :

- +/- 0.2 to +/- 0.3mm for parts of overall size up to 50mm,

- +/- 0.3 to +/- 0.4mm for parts of overall size up to 150mm

- +/- 0.4 to +/- 0.5mm for parts of overall size up to 250mm.

Other Information

| Price | TBD |

| Lead Time | 4~5 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 300×220×180mm |

| Layer height | 100microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best-effort basis for the users as a quick information guide for the material selection.

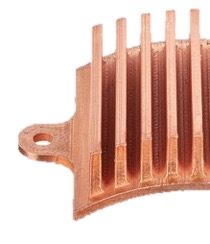

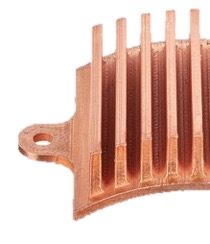

Copper

Copper

Copper possesses better heat and electricity conductivity characteristics and can be formed into any geometrical shape. Application across a wide array of industries from electrical, electronics and automobile etc.

General Characteristics

- Better heat and electricity conductivity

Common Applications

- Welding Shanks

- Induction Coils

- Heatsinks

- Bus Bars

- Custom Fittings

- Adapters

- EDM Electrodes

Mechanical Properties (FDM)

| Tensile strength (UTM) | 193 Mpa |

| Yield Strength | 26 MPa |

| Elongation at break | 45% |

| Thermal conductivity | 350 W/mK |

| Electrical conductivity | 84% ICAS |

| Density | 98.00% |

Other Information

| Price | TBD |

| Lead Time | 4~5 days |

| Wall Thickness | 1mm |

| Tolerances | ±0.5mm |

| Max part size | 300×220×180mm |

| Layer height | 125 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

SLA - Rubber 65A

SLA - Rubber 65A

Figure 4® RUBBER-65A BLK material is created to address the needs for rubber parts featuring production-level performance and mechanical properties tested according to industry standards. Figure 4 RUBBER-65A BLK is a mid-tear strength, high elongation at break, Shore 65A material for the production of medium-hard rubber parts with the slow rebound

General characteristics

- Mid-tier strength

- High elongation at break

- Shore 65A hardness

- Slow rebound

- Easy to clean

Common applications

- Grips

- Handles

- Gaskets

- Bump stoppers

- Seals

- Vibration dampers

- Automotive

- General engineering

- Electrical & electronics

Post-processing

- Painting

Other information

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 124x70x196mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Stainless Steel 316L

Stainless Steel 316L

Stainless steel 316L is a corrosion-resistant iron-based alloy. Parts built from SS 316L can be machined, shot-peened and polished. Parts are not ideal in the temperature range 427°C - 816°C where precipitation of chromium carbides occurs. Due to the layer-wise building method, the parts have a certain anisotropy which could be seen from mechanical properties.

General characteristics

- Corrosion resistant

- High strength

Common Applications

- Automobile

- Aerospace

- Heat exchangers

- Turbine machinery

- Consumer goods

Post-processing

- Machining

- Polishing

Other info

| Price | TBD |

| Lead Time | 3~4 days |

| Wall Thickness | 1mm |

| Tolerances | See below |

| Max part size | 250×250×300mm |

| Layer height | 100 microns |

Accuracy :

- +/- 0.2 to +/- 0.3mm for parts of overall size up to 50mm,

- +/- 0.3 to +/- 0.4mm for parts of overall size up to 150mm

- +/- 0.4 to +/- 0.5mm for parts of overall size up to 250mm.

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

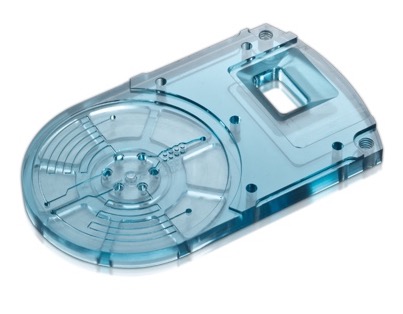

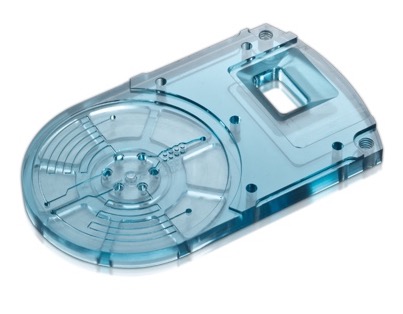

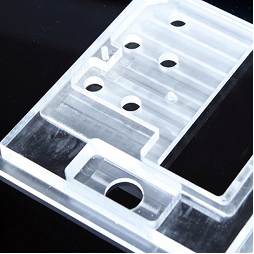

Transparent

Transparent

Accura ClearVue's outstanding merger of clarity, material properties and processing speed makes it a high-performing and cost-effective option for aesthetic and functional prototypes used to improve product development efficiency of consumer goods, automotive, aerospace and medical components.

General characteristics

- Best-in-class optical clarity

- Part stability and water tightness

- Applications versatility

- Beautiful transparent parts

- Ease-of-use and fast processing

Common applications

- Models and prototypes requiring high clarity

- Lighting and lenses

- Fluid flow visualization models

- Transparent assemblies

- Packaging/bottles

- General purpose prototyping

- Prototypes of conformal cooling molds

- Snap fits and complex assemblies

Other information

| Price | TBD |

| Lead Time | ~2 days |

| Wall Thickness | 0.8mm |

| Tolerances | ±0.1mm |

| Max part size | 380x380x250mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only. They have been made available on a best-effort basis for the users as a quick information guide for the material selection.

Ultracur3D® ST45 (BioCompatible)

Ultracur3D® ST45 (BioCompatible)

Best for high-performance functional parts requiring high accuracy and mechanical strength. Biocompatible, with excellent surface quality and the ability to produce fine detail. Ideal applications include housings, enclosures, consumer-facing components, parts requiring textures or highly detailed design features.

Colour - Black

General Characteristics

- Excellent combination of high strength

- Toughness and impact resistance

- Good surface quality and accuracy

- Biocompatible (ISO 10993)

- Flammability: UL-94 (HB)

Common Applications

- Housing & enclosures

- Consumer products

- Textured parts

- High-detailed design features

|

Properties |

Typical Values |

|

Viscosity, 30 °C |

210 MPa |

|

Viscosity, 50 °C |

80 MPa |

|

Density (printed part) |

1.2 g/cm³ |

|

Density (liquid resin) |

1.12 g/cm³ |

|

Tensile Properties |

Typical Values |

|

E Modulus |

2300 MPa |

|

Ultimate Tensile Strength |

60 MPa |

|

Elongation at Break |

25 % |

|

Flexural Properties |

Typical Values |

|

Flexural Modulus |

2400 MPa |

|

Flexural Strength |

110 MPa |

|

Impact Properties |

Typical Values |

|

Notched Izod (Machined), -30 °C |

20 J/m |

|

Notched Izod (Machined), 23 °C |

30 J/m |

|

Unnotched Izod, 23 °C |

509 J/m |

|

Charpy notched, 23 °C |

1.3 kJ/m² |

|

Thermal Properties |

Typical Values |

|

HDT at 0.45 MPa |

73 °C |

|

HDT at 1.82 MPa |

61 °C |

|

Flammability |

HB |

|

Glow-wire Test |

GWIT: 650°C GWFI: 625°C |

|

Hardness |

Typical Values |

|

Shore D |

80 |

|

Other |

Typical Values |

|

Biocompatibility |

ISO 10993 |

Other Information

| Price | TBD |

| Lead Time | 4~5 days |

| Wall Thickness | 0.8mm |

| Tolerances | ±0.1mm |

| Max part size | 192x108x370 mm |

| Layer height | 100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

SLA - Fig4 HI TEMP 300

SLA - Fig4 HI TEMP 300

Figure 4 HI TEMP 300-AMB is an ultra-high temperature plastic for applications requiring high heat resistance. It is the industry’s highest heat-resistant material with a heat deflection temperature of over 300 °C. This material is well suited for the testing of high-temperature components in applications including HVAC, consumer appliances, motor enclosures, stators, molds, and the like.

General Characteristics

- HDT over 300°C

- Rigid and translucent

- Production-grade material

- High tensile modulus for use in molds

- High heat resistance for testing and use in high-heat environments

- Excellent visualization for parts requiring evaluation of internal features and fluid flow performance

Common Applications

- HVAC

- Stators

- Rubbers

- Over molding

- Motor enclosures

- Expanding foams

- Consumer appliances

Mechanical properties

|

Tensile modulus (Young Mod) |

4000 MPa |

|

Tensile strength (UTM) |

81 MPa |

|

Elongation at break |

2.60% |

|

Flexural strength |

140 MPa |

|

Flexural modulus |

4260 MPa |

|

Hardness |

89D |

|

Heat deflection temp (Td) |

300˚C |

|

Density (Solid) |

1.3gm/cm3 |

Other information

|

Price |

TBD |

|

Lead Time |

2~3 days |

|

Wall Thickness |

1mm |

|

Tolerances |

±0.1mm |

|

Max part size |

- |

|

Layer height |

100 microns |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best-effort basis for the users as a quick information guide for the material selection.

Stellite 6 alloy

Stellite 6 alloy

STELLITE 6 is the most widely used of the wear-resistant cobalt-based alloys and exhibits good all-round performance. It is regarded as the industry standard for general-purpose wear-resistance applications, has excellent resistance to many forms of mechanical and chemical degradation over a wide temperature range, and retains a reasonable level of hardness up to 500°C (930°F). It also has good resistance to impact and cavitation erosion.

General Characteristics

- High wear-resistant

- Retains hardness

- Corrosion resistance

Common Applications

- Valve seats and gates

- Pump shafts and bearings,

- Erosion shields

- Rolling couples

Post processing

- Machining

Mechanical Properties

| Tensile strength (UTM) | 850MPa |

| Yield Strength | 700MPa |

| Elongation at break | <1% |

| Modulus of elasticity | 209MPa |

| Hardnes | 36-45HRC |

| Melting Temp. | 1250-1360˚C |

| Thermal conductivity | 14.82 W/m.K |

| Electrical resistivity | 106 μ-ohm.cm |

| Density (Solid) | 8.44 g/cm³ |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for material selection.

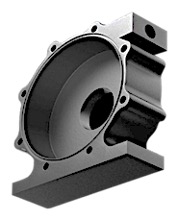

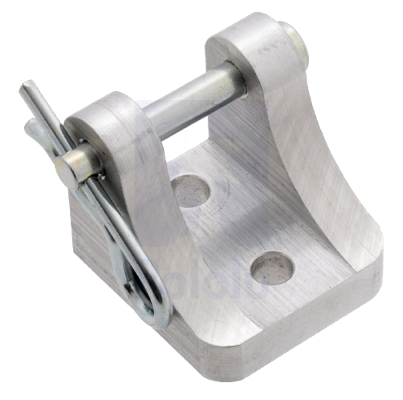

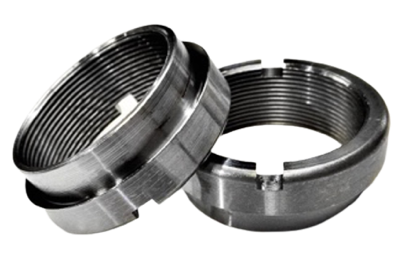

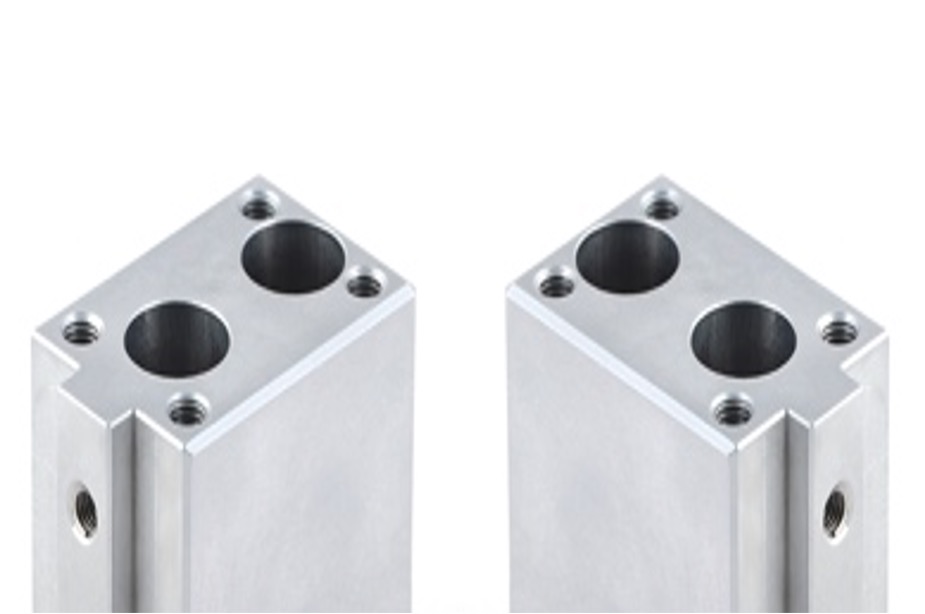

CNC Machining

Aluminum 6061

Aluminum 6061

Aluminum 6061 is an extremely popular alloy, excellent for jobs that require forming or welding. It is the most commonly available aluminum alloy and provides a clean surface finish. Unlike other aluminum alloys, 6061 has high corrosion resistance. It can be forged, hot worked, and readily welded, as well as heat treated, annealed, and aged. It anodizes well and provides a bright, colourful finish.

General Characteristics

- Weldability

- Good formability

- Corrosion resistance

Common Applications

- Electronic hardware

- Recreation equipment

- Piping

- Aircraft components

- General engineering applications

Material properties

| Al 6061 | Al 6061-T6 (Hardened) | |

| Temper | - | T6 |

| Modulus of elasticity / Young Mod. | 68 GPa | 68 GPa |

| Yield Strength | 55.2 MPa | 276 MPa |

| Ultimate Tensile strength | 124 MPa | 310 MPa |

| Elongation at break | 25% | 12 - 17% |

| Hardness | 30 HRB | 60 HRB |

| Max Working temp. | 130 - 150˚C | 130 - 150˚C |

| Thermal expansion coefficient | 23.6 µm/m-°C | 23.6 µm/m-°C |

| Thermal conductivity | 180 W/m-°C | 167 W/m-°C |

| Electrical resistivity | 3.6 μΩ-cm | 3.9 μΩ-cm |

| Corrosion | High Resistance | High Resistance |

| Welding | High weldability | High weldability |

Post-processing

- Annealing

- Cold working

- Anodizing compatible

Other info

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Aluminum 7075-T6

Aluminum 7075-T6

Aluminum alloy 7075 is the strongest of available aluminum alloys with zinc as a major element, excellent for jobs that require extreme strength while remaining lightweight. It possesses great cracking resistance and can be forged and heat-treated but is not ideal for welding. 7075 can be heat treated, annealed, and aged. It is not as ideal for anodizing compared to Aluminum 6061 and may produce a yellowish tint when clear anodizing.

General Characteristics -

- High Strength

- Good machinability.

Common Applications -

- Aerospace

- Automotive

Material properties -

| Temper | T6 |

| Modulus of elasticity / Young Mod. | 71 GPa |

| Yield Strength | 503 MPa |

| Ultimate Tensile strength | 572 MPa |

| Elongation at break | 11% |

| Hardness | 87 HRB |

| Max Working temp. | 100˚C |

| Thermal expansion coefficient | 23.6 µm/m-°C |

| Thermal conductivity | 129 W/m-°C |

| Electrical resistivity | 5.15 μΩ-cm |

| Corrosion | Moderate Resistance |

| Welding | Poor Weldability |

Post-processing -

- Annealing

- Cold working

- Anodizing compatible

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Aluminum 2024-T6

Aluminum 2024-T6

Aluminum alloy 2024 is an exceptionally high mechanical strength alloy, suitable for parts that require more strength while remaining lightweight. It also has excellent fatigue and cracking resistance, making it a desirable material for automotive & aircraft components. Aluminum 2024 can be machined to a high finish. It can be forged and hot worked but is not ideal for welding or soldering. 2024 responds well to heat treatment, annealing, and tempering. It can be anodized but results in a darker and less corrosion-resistant finish than Aluminum 6061.

General Characteristics -

- Improved strength

- High fatigue

- Cracking resistance

Common Applications -

- Electronic hardware

- Aircraft components

- Automotive parts

- Structural applications

Material properties -

| Temper | T6 |

| Modulus of elasticity / Young Mod. | 74 GPa |

| Yield Strength | 345 MPa |

| Ultimate Tensile strength | 427 MPa |

| Elongation at break | 5% |

| Hardness | 78 HRB |

| Max Working temp. | 190˚C |

| Thermal expansion coefficient | 23.2 µm/m-°C |

| Thermal conductivity | 151 W/m-°C |

| Electrical resistivity | 4.49 μΩ-cm |

| Corrosion | Poor Resistance |

| Welding | Good Weldability |

Post-processing -

- Hot & cold working

- Anodizing compatible

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Aluminum MIC6

Aluminum MIC6

MIC6 Cast aluminum tooling plate offers superior dimensional stability and flatness compared to 6061 rolled plates. Being a cast product, it possesses very low internal stresses. Fully stress-relieved, Mic6 is a free-cutting aluminum alloy with excellent machining characteristics. Additionally, it is lightweight, smooth, and free from tension, contaminants, and porosity.

Common Applications -

- Tooling, base plates

- Jigs and fixtures

- Gauges

- Rubber

- Plastic molds

Material properties -

| Modulus of elasticity / Young Mod. | 71 GPa |

| Yield Strength | 105 MPa |

| Ultimate Tensile strength | 165 MPa |

| Elongation at break | 3% |

| Hardness | 65 HB |

| Max Working temp. | 400˚C |

| Thermal expansion coefficient | 23.6 µm/m-°C |

| Thermal conductivity | 142 W/m-°C |

| Electrical resistivity | 4.79 μΩ-cm |

| Corrosion | Good Resistance |

| Welding | Good Weldability |

Post-processing -

- Anodizing compatible

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Copper C110

Copper C110

Copper alloy 110 is an extremely popular copper alloy, with a wide range of applications due to its high corrosion resistance, conductivity, and finish. It has the highest electrical conductivity of any metal, except silver. When exposed to the elements, it forms a thin protective patina that is relatively impermeable. Copper 110 is ideal when extensive machining is not required, as it has extremely low machinability compared to other copper alloys. It is excellent for hot and cold forming, as well as soldering. Copper 110 is not easily welded or brazed.

General Characteristics -

- High corrosion resistance

- High Conductivity

- High finish

Common Applications -

- Electrical contacts

- Electrical instruments & fittings

Material properties -

| Temper | Annealed |

| Modulus of elasticity / Young Mod. | 117 GPa |

| Yield Strength | 283 - 345 MPa |

| Ultimate Tensile strength | 296 - 359 Mpa |

| Elongation at break | 3 - 16% |

| Hardness | 57 HRB |

| Thermal expansion coefficient | 17.6 µm/m-°C |

| Thermal conductivity | 390 W/m-°C |

| Electrical resistivity | 1.76 μΩ-cm |

| Welding | Moderate Weldability |

Post-processing -

- Not suitable for anodizing

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Copper C101

Copper C101

Copper alloy C101 is the designation for moderate copper used in engineering applications. High ductility and impact strength also serve to make an extremely useful material. Copper alloy C101 is also known as HC or high conductivity copper and also has high thermal conductivity. Copper alloy C101 is, therefore, the material of choice for use in conductors and electrical components. It has a very high percentage of Copper in it - 99.9%.

General Characteristics -

- Excellent ductility

- Can be readily cold worked

- Good corrosion resistance

Common Applications -

- General engineering

- Electronics

- Automotive

- Domestic Appliances

- Cold-formed components

Material properties -

| Modulus of elasticity / Young Mod. | 115 GPa |

| Yield Strength | 69 - 365 MPa |

| Ultimate Tensile strength | 221 - 455 MPa |

| Elongation at break | 55% |

| Hardness | 75 - 90 HV |

| Thermal expansion coefficient | 17 µm/m-°C |

| Thermal conductivity | 383 - 391 W/m-°C |

| Electrical resistivity | 1.74 μΩ-cm |

| Corrosion | Good to excellent |

| Welding | Poor Weldability |

Post-processing -

- Not suitable for anodizing

Other info -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Brass C360

Brass C360

Brass CDA 360 alloy has the highest machinability of all copper alloys, extremely popular for parts that require strength, weight, or a polished surface finish. Brass 360 has a very wide range of applications and is ideal for industrial and electronic industries. Unlike steel, 360 also forms a thin protective patina that does not rust. It has fair hot forming properties and is not ideal for cold forming, welding, soldering, and brazing. Brass 360 can be forged and annealed.

General Characteristics -

- Good corrosion resistance

- Tensile strength

Common Applications -

- Electronic hardware

- Contacts fittings

- Numerous commercial products

Material properties -

| Modulus of elasticity / Young Mod. | 97 GPa |

| Yield Strength | 124 - 310 MPa |

| Ultimate Tensile strength | 338 - 469 MPa |

| Elongation at break | 53% |

| Hardnes | 63 HB |

| Thermal expansion coefficent | 20.5 µm/m-°C |

| Thermal conductivity | 115 W/m-°C |

Post-processing -

- Annealing

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Mild steel 1018

Mild steel 1018

AISI 1018 mild/low carbon steel has excellent weldability, produces a uniform and harder case, and is considered the best steel for carburized parts. AISI 1018 mild/low carbon steel offers a good balance of toughness, strength, and ductility. It produces exceptional welds that do not require pre- or post-heating processes. 1018 responds well to case hardening and heat treating.

General Characteristics -

- Excellednt weldability

- Tough & ductile

Common Applications -

- Shafts

- Spindles

- Pins

- Rods

- Sprocket assemblies

Material properties -

| Modulus of elasticity / Young Mod. | 200 GPa |

| Yield Strength | 370 MPa |

| Ultimate Tensile strength | 440 MPa |

| Elongation at break | 15% |

| Hardness | 71 HRB |

| Thermal expansion coefficient | 12.1 µm/m-°C |

| Thermal conductivity | 51.9 W/m-°C |

| Electrical resistivity | 15.9 μΩ-cm |

| Corrosion | Poor Resistance |

| Welding | High weldability |

Post-processing -

- Not suitable for anodizing

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Mild Steel 1045

Mild Steel 1045

Steel alloy 1045 is a versatile medium carbon alloy, ideal for parts that require strength and impact resistance. Due to its higher carbon content, it has higher tensile strength. 1045 has excellent ductility and toughness. It is not ideal for welding or forming due to its higher carbon content. 1045 responds to heat treatment extremely well, but it is not ideal for case hardening.

General Characteristics -

- High strength,

- Impact resistance

- Higher tensile strength

Common Applications -

- Rods

- Dies

- Bolts

- Gears

Material properties -

| Modulus of elasticity / Young Mod. | 206 GPa |

| Yield Strength | 330 - 580 MPa |

| Ultimate Tensile strength | 606 - 682 MPa |

| Elongation at break | 13 - 18% |

| Hardness | 89 HRB |

| Thermal expansion coefficient | 12.1 µm/m-°C |

| Thermal conductivity | 51.9 W/m-°C |

| Electrical resistivity | 16 - 19 μΩ-cm |

| Corrosion | Poor Resistance |

| Welding | Good Weldability |

Post-processing -

- Annealing

- Cold working

- Not suitable for Anodizing

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Alloy Steel 4140

Alloy Steel 4140

Steel alloy 4140 cold roll is a popular general-purpose alloy, ideal for parts that require high tensile strength and toughness. It has considerable atmospheric corrosion and wear resistance, and will not become brittle. It is not ideal for welding due to its lead content. It is often used for forging, responds very well to heat treatment, and can be annealed.

General Characteristics -

- High strength

- High toughness

- Corrosion-resistant

Common Applications -

- Gears

- Shafts

- Pins

- Bolts and nuts

- Pump and valve components

Material properties -

| Modulus of elasticity / Young Mod. | 206 GPa |

| Yield Strength | 660 - 965 MPa |

| Ultimate Tensile strength | 896 - 1103 MPa |

| Elongation at break | 17 - 22% |

| Hardnes | 97 HRB |

| Thermal expansion coefficent | 12.1 µm/m-°C |

| Thermal conductivity | 42 W/m-°C |

| Electrical resistivity | 22 μΩ-cm |

| Corrosion | Good Resistance |

| Welding | Moderate Weldability |

Post-processing -

- Annealing

- Cold working

- Not suitable for Anodizing

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Alloy Steel 1215

Alloy Steel 1215

Steel alloy 1215 is a popular free-machining alloy (FMA), ideal for parts that require considerable machining and a bright finish. It responds well to slight bending, threading, and nibbling, but is not ideal for parts that may be subject to very severe fatigue stress. It possesses better weldability and formability and can be heat treated.

General Characteristics -

- Good weldability & formability

Common Applications -

- Bushings

- Pins

- Inserts

- Couplings

- Fittings

Material properties -

| Modulus of elasticity / Young Mod. | 200 GPa |

| Yield Strength | 415 MPa |

| Ultimate Tensile strength | 540 MPa |

| Elongation at break | 10% |

| Hardnes | 85 HRB |

| Thermal expansion coefficent | 11.5 µm/m-°C |

| Thermal conductivity | 51.9 W/m-°C |

| Electrical resistivity | 17.4 μΩ-cm |

| Corrosion | Good Resistance |

| Welding | Good Weldability |

Post-processing -

- Annealing

- Cold working

- Not suitable for Anodizing

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

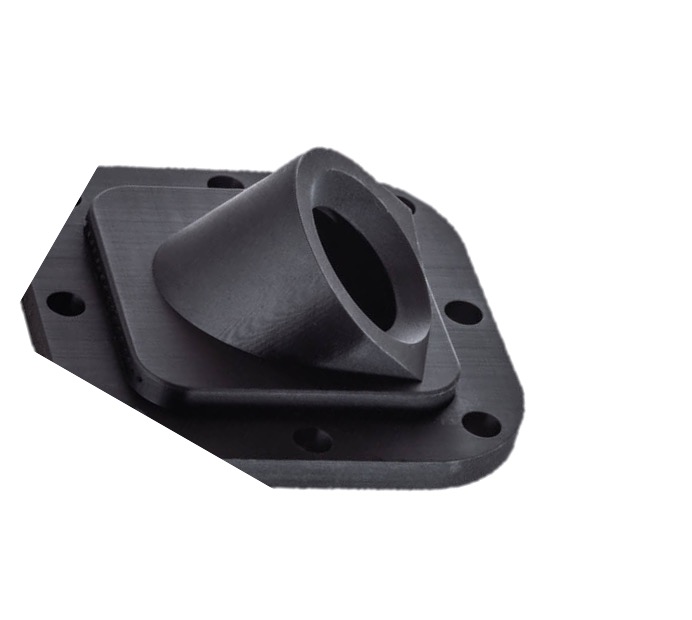

ABS

ABS

ABS(Acrylonitrile Butadiene Styrene) blocks can be processed with ease and versatility. They can be machined, turned, drilled, milled, sawed, bored, die-cut, routed, and sheared using high-speed cutting tools. ABS can be machine finished by filing, grinding, sanding, buffing, and polishing.

Color - Natural, black

General Characteristics -

- High rigidity

- High impact strength

- Excellent abrasion resistance

Common Applications -

- Machine parts

- Rollers

- Pipes & fittings

- Trays

Material properties -

| Modulus of elasticity / Young Mod. | 1.83 - 2.21 Gpa |

| Yield Strength | 31.0 - 42.7 MPa |

| Ultimate Tensile strength | 15.9 - 39.9 MPa |

| Elongation at break | 10 - 50% |

| Flexural Strength | 34.5 - 77.9 |

| Hardness | 80.0 - 105 HRR |

| Max Working temp. | Upto 70˚C |

| Thermal expansion coefficient | 59.4 - 101 µm/m-°C |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Delrin

Delrin

Delrin (POM-H) is a versatile low-cost plastic in the acetal family, ideal for parts that require strength and resilience while machining to very tight tolerances. It has excellent dimensional stability and friction resistance, making it long-wearing. Unlike nylon, it has a very low moisture absorption rate, making it suitable for use in wet environments.

Color - Black & white

General Characteristics -

- Self-lubrication tendency

- High hardness

- Good wear & fatigue resistance

- Electrical insulation

- Dimensionally stable

Common Applications -

- Gears

- Bearings

- Conveyor parts

- Automotive parts

- Sporting equipment

- Electrical components

- Sliding & guiding parts

Material properties -

| Modulus of elasticity / Young Mod. | 3.1 GPa |

| Ultimate Tensile strength | 75 MPa |

| Elongation at break | 30% |

| Flexural Strength | 89 MPa |

| Compressive Strength | 103 MPa |

| Hardness | 122 HRR |

| Max Working temp. | Upto 80˚C |

| Thermal expansion coefficient | 84 µm/m-°C |

| Thermal conductivity | 0.360 W/m-˚C |

| UV Resistance | Moderate |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Nylon

Nylon

Nylon is a versatile low-cost plastic, ideal for parts that require high compressive strength and friction resistance while machining to very tight tolerances. It can be used in place of metal in some applications, allowing for longer-wearing parts that require lower maintenance than its metal counterpart. Nylon generally is stronger, withstands higher temperatures.

Color - Black, white

General Characteristics -

- Good machining

- High friction resistance

Common Applications -

- Insulators

- Gears

- Bearings

- Bushings

Material properties -

| Modulus of elasticity / Young Mod. | 2.76 GPa |

| Ultimate Tensile strength | 82 MPa |

| Elongation at break | 30% |

| Flexural Strength | 110 MPa |

| Compressive Strength | 103 MPa |

| Hardnes | 115 HRR |

| Max Working temp. | Upto 90˚C |

| Thermal expansion coefficent | 90 µm/m-°C |

| Thermal conductivity | 0.24 W/m-˚C |

| UV Resistance | Moderate |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

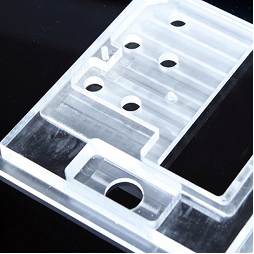

Acrylic

Acrylic

Acrylic(PMMA) has excellent weathering resistance, especially applied to outdoor, ranking the highest in other plastics, and both a good surface hardness and gloss, processing plasticity, can be made of the required shape and products. Has extremely superior optical performance. Excellent transparency, light transmission rate of 92%, and can also be safe to use outdoor.

Color - Transparent

General Characteristics -

- UV stable

- scratch-resistant

- Resistant to salty water

- Dimensionally stable

Common Applications -

- Fixtures

- Decoration

- Exhibitions

- Lighting lamp

- Craft products

- Advertising signs

- Medical equipment

- Avionics and transportation

Material properties -

| Modulus of elasticity / Young Mod. | 3.3 GPa |

| Yield Strength | 72 MPa |

| Ultimate Tensile strength | 35 MPa |

| Elongation at break | 5% |

| Flexural Strength | 105 MPa |

| Compressive Strength | 103 MPa |

| Hardnes | 80 - 100 HRM |

| Max Working temp. | Upto 70˚C |

| Thermal expansion coefficent | 70 µm/m-°C |

| Thermal conductivity | 0.19 W/m-˚C |

| UV Resistance | Good |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

PEEK

PEEK

Polyether ether ketone (PEEK) is a popular high-strength plastic resin, ideal for parts that require strength and stiffness. It has an extremely high resistance to heat, moisture, and chemicals and can withstand multiple cycles in hot water or steam. PEEK also performs well in ultra-high vacuum environments.

Color - Black

General Characteristics -

- High strength plastic

- Extremely high resistance to heat, moisture, and chemicals

Common Applications -

- Bearings

- Bushings

- Pump components

- Aerospace components

Material properties -

| Modulus of elasticity / Young Mod. | 4.3 GPa |

| Ultimate Tensile strength | 110 MPa |

| Elongation at break | 40% |

| Flexural Strength | 172 MPa |

| Compressive Strength | 138 MPa |

| Hardness | 126 HRR |

| Max Working temp. | Upto 240˚C |

| Thermal expansion coefficient | 46.8 µm/m-°C |

| Thermal conductivity | 0.25 W/m-˚C |

| UV Resistance | Good |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

Teflon (PTFE)

Teflon (PTFE)

PTFE (Polytetrafluoroethylene) commonly known as Teflon is an extremely resilient plastic, ideal for screw machine parts that require high-impact strength and durability. It has excellent resistance to frictional wear, weathering, flame, heat, chemicals, and radiation. Teflon is not affected by the ultraviolet and is resistant to oxidation, discolouration, and embrittlement. Teflon is completely resistant to hydrolysis. Teflon is a good barrier for water permeation.

Color - Black

General Characteristics -

- High impact strength and durability

- Resistance to frictional wear, weathering, flame, heat, chemicals, and radiation

Common Applications -

- Insulators

- Bearings

- Spacers

- Valve components

Material properties -

| Modulus of elasticity / Young Mod. | 0.4 - 0.5 GPa |

| Yield Strength | 19 MPa |

| Ultimate Tensile strength | 20 - 34 MPa |

| Elongation at break | 2 - 4% |

| Hardnes | 5.9 - 6.5 HV |

| Max Working temp. | Upto 260˚C |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Polycarbonate

Polycarbonate

Polycarbonate is a transparent thermoplastic material with good strength and stiffness and outstanding impact resistance. It provides the best mechanical property and electrical insulation, high dimensional stability and excellent creep resistance. Polycarbonate's toughness and optical clarity make it ideal for a wide variety of applications. And it can be used in temperatures up to +110°C.

Color - Black, White, Semi-transparent

General Characteristics -

- Strong, stiff, and outstanding toughness

- High impact resistance

- Good optical clarity (transparent)

Common Applications -

- Impact strength parts

- Architectural glazing, skylights, transparent manifolds

- semiconductor machinery components

- Optical materials

- Lighting materials

Material properties -

| Modulus of elasticity / Young Mod. | 2 GPa |

| Yield Strength | 60 - 70 MPa |

| Ultimate Tensile strength | 61 MPa |

| Elongation at break | 50 - 120% |

| Flexural Strength | 90 MPa |

| Compressive Strength | 17.7 - 21.7 HV |

| Hardnes | 77 HRM |

| Max Working temp. | Upto 110˚C |

| Thermal expansion coefficent | 68 µm/m-°C |

| Thermal conductivity | 0.89 - 0.21 W/m-˚C |

| UV Resistance | Moderate |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Polypropylene

Polypropylene

Polypropylene (PP) is an economical material that offers a combination of outstanding physical, chemical, mechanical, thermal, and electrical properties not found in any other thermoplastic. Polypropylene has excellent chemical resistance in corrosive environments where there are organic solvents, degreasing agents, or electrolytic attacks, but poor resistance to aromatic, aliphatic, and chlorinated solvents. It is lightweight, non-staining, and exhibits a low moisture absorption rate. It’s ideal for the transfer of hot liquids and gases, and in vacuum system atmospheres with high heat and pressure.

Color - White

General Characteristics -

- Greater tensile strength

- Excellent chemical resistance

- Lightweight

Common Applications -

- Sealing

- Barrels

- Acid industry

- Spray carrier

- Drinking pipe accessories

- Corrosion-resistant tank

- Wastewater emission equipment

Material properties -

| Modulus of elasticity / Young Mod. | 2 GPa |

| Yield Strength | 60 - 70 MPa |

| Ultimate Tensile strength | 61 MPa |

| Elongation at break | 50 - 120% |

| Flexural Strength | 90 MPa |

| Compressive Strength | 17.7 - 21.7 HV |

| Hardness | 77 HRM |

| Max Working temp. | Upto 110˚C |

| Thermal expansion coefficient | 68 µm/m-°C |

| Thermal conductivity | 0.89 - 0.21 W/m-˚C |

| UV Resistance | Moderate |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 500x500x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

GF Nylon

GF Nylon

30% glass-filled nylon is suitable for use in the automotive industry & other general engineering applications where very high strength & resistance to high temperature is key. It also provides high strength and rigidity.

General Characteristics

- Tough

- versatile

- Good heat resistance

- High friction resistance

- cost-effective engineering thermoplastic

- Good balance of impact and tensile strengths

Common Applications

- Automotive

- Electrical & electronics

Post-processing

- Painting

Other information

| Price | TBD |

| Lead Time | ~5 days |

| Max part size | 400x400x500mm |

Disclaimer - Material properties are for general-purpose reference only and have been made available on a best effort basis for the users as a quick information guide for the material selection.

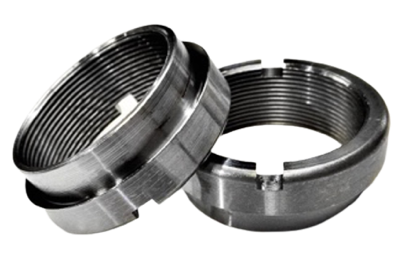

Stainless Steel 316L

Stainless Steel 316L

Stainless steel 316 is the standard molybdenum-bearing grade, second in importance to 304 amongst the austenitic stainless steels. The molybdenum gives 316 better overall corrosion-resistant properties than Grade 304, notably higher resistance to pitting and crevice corrosion in chloride environments. 316L stainless steel offers higher creep, stress to rupture and tensile strength at elevated temperatures.

General characteristics